- Home

- About Us

- Products

- Hydraulic Cylinders

- Forklift Hydraulic Cylinders

- Agricultural Machinery Hydraulic Cylinders

- Aerial Work Vehicle Hydraulic Cylinders

- Sanitation Machinery Hydraulic Cylinders

- Construction Machinery Hydraulic Cylinders

- Mobile Machinery Hydraulic Cylinders

- Industrial Engineering Hydraulic Cylinders

- American Standard Series Hydraulic Cylinders

- Offshore Hydraulic Cylinders

- Energy Technology Hydraulic Cylinders

- Tunnel Boring Machine Hydraulic Cylinders

- Telescopic Hydraulic Cylinders

- Tractor & Front End Loader Hydraulic Cylinders

- Steering Hydraulic Cylinders

- Dump Truck & Trailer Hydraulic Cylinders

- Electirc and Instrument

- Gasification station

- Equipment

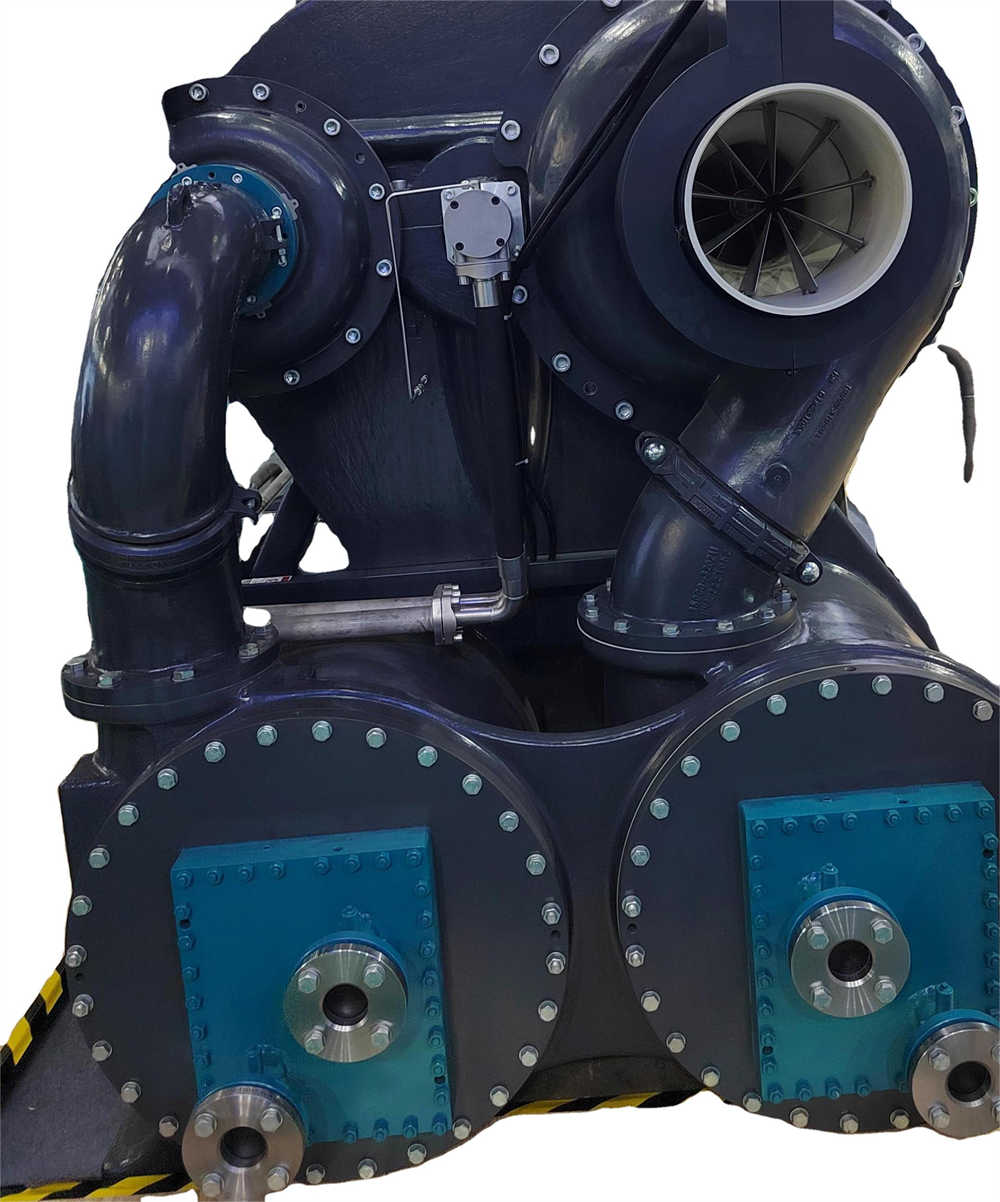

- Gas compressor

- Gas filter and purification

- Gas Storage & transportation

- Air separation plant

- Refrigeration Equipment

- Ungrouped

- Hydraulic Cylinders

- News

- Download

- Send Inquiry

- Contact Us

Tractor & Front End Loader Hydraulic Cylinders

What Are Tractor & Front End Loader Hydraulic Cylinders?

Tractor and front end loader hydraulic cylinders are essential components in agricultural and construction machinery, providing the force needed for lifting, pushing, and pulling operations. These cylinders convert hydraulic energy into mechanical motion, enabling efficient handling of heavy loads. Designed for durability and high performance, they are critical for tasks such as loading materials, digging, and maneuvering equipment in various conditions. With robust construction and precision engineering, these cylinders ensure reliability and longevity in demanding environments, making them a vital part of modern machinery.

Key Product Parameters

Our tractor and front end loader hydraulic cylinders are engineered to meet rigorous standards, offering exceptional strength and efficiency. Below are the detailed parameters presented in lists and a table for clarity.

General Specifications

- Bore Size: Available in diameters ranging from 2 inches to 8 inches, catering to different load capacities.

- Stroke Length: Customizable from 10 inches to 60 inches, allowing for versatile application needs.

- Operating Pressure: Rated for up to 3000 PSI, ensuring high performance under heavy loads.

- Material: Constructed from high-grade steel with chrome-plated rods for corrosion resistance and durability.

- Seals: Equipped with premium polyurethane seals to prevent leaks and withstand harsh conditions.

- Mounting Styles: Various options including clevis, flange, and trunnion mounts for easy integration.

Detailed Parameter Table

| Parameter | Range | Description |

|---|---|---|

| Bore Diameter | 2" - 8" | Determines the force output; larger bores handle heavier loads. |

| Stroke Length | 10" - 60" | Length of piston travel; customizable for specific machinery requirements. |

| Max Operating Pressure | 3000 PSI | Maximum pressure the cylinder can endure without failure. |

| Rod Diameter | 1" - 5" | Size of the piston rod; affects stability and load capacity. |

| Material Grade | ASTM A36 Steel | High-strength steel with anti-corrosion treatment for longevity. |

| Weight Capacity | Up to 10,000 lbs | Maximum load the cylinder can lift or push effectively. |

| Temperature Range | -40°F to 250°F | Operational limits in various environmental conditions. |

Applications and Benefits

Tractor and front end loader hydraulic cylinders are used in a wide range of applications, from agriculture to construction. They provide superior lifting power for tasks like moving soil, loading goods, and operating attachments. Benefits include enhanced efficiency, reduced manual labor, and improved safety due to reliable performance. These cylinders are designed to minimize maintenance needs, with features like self-lubricating seals and robust materials that resist wear and tear. Whether for small farms or large industrial sites, they offer customizable solutions to fit specific machinery and operational demands.

FAQ Section

What is the typical lifespan of a tractor hydraulic cylinder?

The lifespan varies based on usage and maintenance, but with proper care, these cylinders can last 5-10 years or more. Regular inspections and timely seal replacements can extend durability.

How do I choose the right bore size for my tractor?

Select the bore size based on the required force output; larger bores provide more power. Consult your machinery manual or a professional to match the cylinder to your tractor's specifications.

Can these cylinders be used in extreme weather conditions?

Yes, they are designed to operate in temperatures from -40°F to 250°F, with materials and seals that withstand harsh environments, including rain, dust, and temperature fluctuations.

What maintenance is required for hydraulic cylinders?

Routine maintenance includes checking for leaks, inspecting seals, and ensuring proper hydraulic fluid levels. Lubricate moving parts annually and replace seals every 1-2 years depending on usage.

Are custom stroke lengths available?

Absolutely, we offer customizable stroke lengths from 10 to 60 inches to fit specific application needs, ensuring optimal performance for your machinery.

What causes hydraulic cylinder failure, and how can it be prevented?

Common causes include seal leaks, contamination, and overpressure. Prevent failure by using clean hydraulic fluid, maintaining correct pressure levels, and conducting regular inspections.

Can I install these cylinders myself, or do I need a professional?

While simple replacements might be DIY for experienced users, complex installations or integrations with hydraulic systems should be handled by professionals to ensure safety and functionality.

Do you provide warranties for these products?

Yes, our cylinders come with a standard warranty covering defects in materials and workmanship, typically for 1-2 years, with options for extended coverage based on the product.

How does operating pressure affect performance?

Higher operating pressure allows the cylinder to handle heavier loads, but it must not exceed the rated limit to avoid damage. Always operate within the specified PSI range for safety.

What are the signs that a hydraulic cylinder needs replacement?

Look for symptoms like slow operation, fluid leaks, uneven movement, or visible damage to the rod. If repairs don't resolve these issues, replacement may be necessary.