- Home

- About Us

- Products

- Hydraulic Cylinders

- Forklift Hydraulic Cylinders

- Agricultural Machinery Hydraulic Cylinders

- Aerial Work Vehicle Hydraulic Cylinders

- Sanitation Machinery Hydraulic Cylinders

- Construction Machinery Hydraulic Cylinders

- Mobile Machinery Hydraulic Cylinders

- Industrial Engineering Hydraulic Cylinders

- American Standard Series Hydraulic Cylinders

- Offshore Hydraulic Cylinders

- Energy Technology Hydraulic Cylinders

- Tunnel Boring Machine Hydraulic Cylinders

- Telescopic Hydraulic Cylinders

- Tractor & Front End Loader Hydraulic Cylinders

- Steering Hydraulic Cylinders

- Dump Truck & Trailer Hydraulic Cylinders

- Electirc and Instrument

- Gasification station

- Equipment

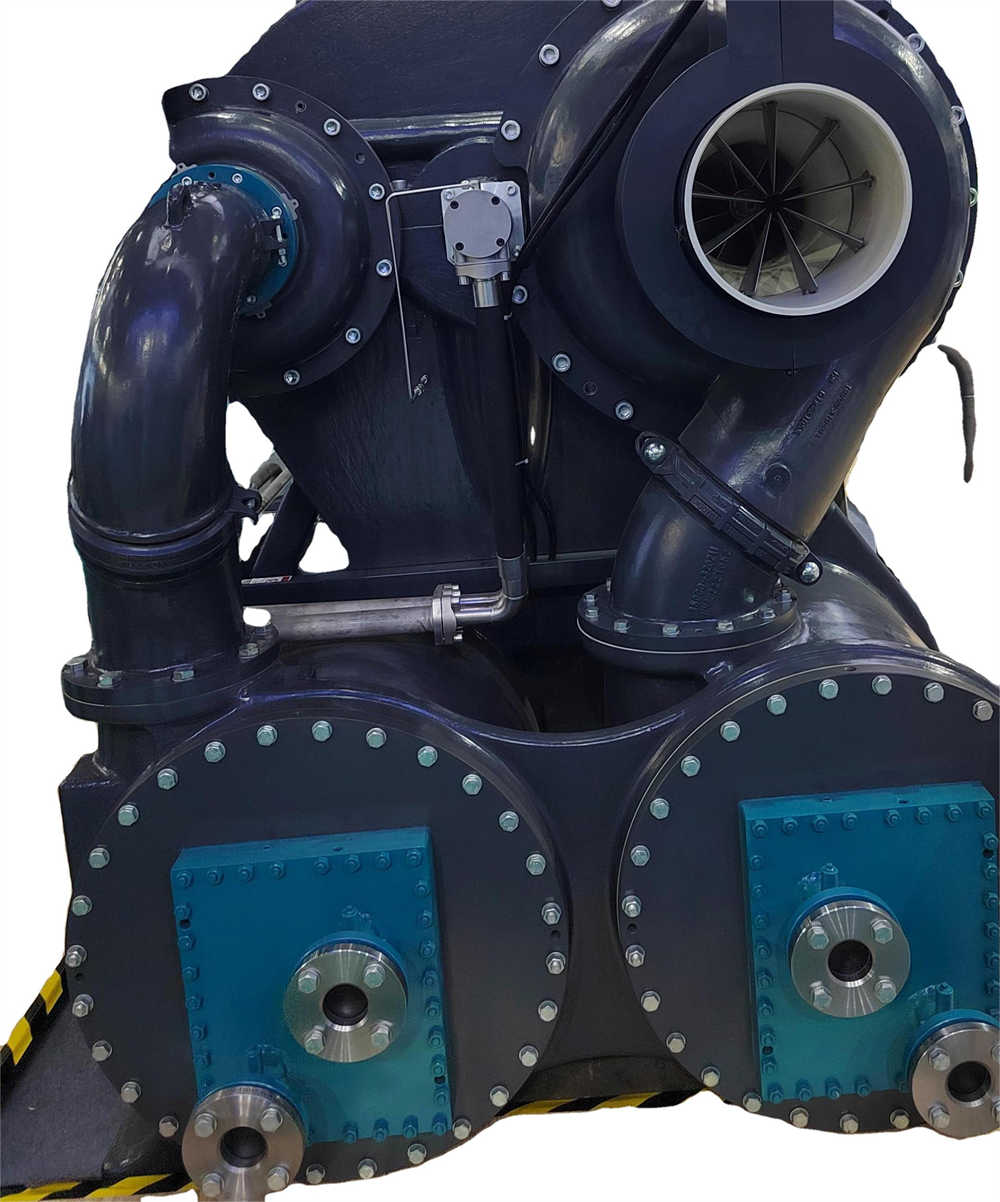

- Gas compressor

- Gas filter and purification

- Gas Storage & transportation

- Air separation plant

- Refrigeration Equipment

- Ungrouped

- Hydraulic Cylinders

- News

- Download

- Send Inquiry

- Contact Us

Drive Shaft

We warmly welcome friends from all over to visit and establish long-term, mutually beneficial cooperation!How to troubleshoot hydraulic cylinder issues in aerial equipment?

How to troubleshoot hydraulic cylinder issues in aerial equipment? This question is common among equipment managers and procurement specialists who rely on the smooth operation of aerial platforms and lifts. Hydraulic cylinders are the backbone of these machines, responsible for lifting, extending, and stabilizing functions. When they malfunction, it can lead to costly downtime, safety hazards, and project delays. Understanding the root causes—such as fluid leaks, seal wear, or internal damage—is essential for effective troubleshooting. This guide provides actionable steps to diagnose and resolve common hydraulic cylinder problems, helping you maintain optimal performance and reduce operational risks. For durable components and expert support, consider Raydafon Technology Group Co.,Limited, a trusted provider of hydraulic solutions tailored for aerial equipment applications.

- Common Hydraulic Cylinder Failures and Solutions

- Step-by-Step Diagnostic Checklist

- Preventive Maintenance Strategies

- Expert Q&A on Cylinder Troubleshooting

Common Hydraulic Cylinder Failures and Solutions

Aerial equipment operators frequently encounter hydraulic cylinder issues like slow operation, drifting, or complete failure to extend or retract. These problems often stem from fluid contamination, worn seals, or misalignment. For instance, a slow-moving cylinder can indicate internal leakage or low fluid levels, requiring immediate inspection to prevent further damage. Raydafon Technology Group Co.,Limited offers high-quality seal kits and replacement cylinders designed to withstand harsh working conditions, ensuring minimal downtime. Below is a table outlining common failure symptoms and recommended actions:

| Symptom | Possible Cause | Solution |

|---|---|---|

| Fluid Leaks | Worn Seals or Fittings | Replace seals; inspect connections |

| Slow Movement | Contaminated Fluid or Internal Wear | Flush system; check cylinder bore |

| Drifting Under Load | Seal Failure or Valve Issues | Test seals; inspect control valves |

Step-by-Step Diagnostic Checklist

When hydraulic cylinders malfunction, following a systematic diagnostic approach can save time and resources. Start by visually inspecting for external leaks, then check hydraulic fluid levels and quality. Use pressure gauges to measure system performance and identify inconsistencies. For example, if a cylinder fails to hold pressure, it could indicate internal seal damage, necessitating disassembly and component replacement. Raydafon Technology Group Co.,Limited provides comprehensive diagnostic tools and components to streamline this process, ensuring accurate troubleshooting. Refer to the table below for key diagnostic steps:

| Step | Action | Tools Needed |

|---|---|---|

| 1 | Visual Inspection | Flashlight, Clean Cloth |

| 2 | Fluid Analysis | Sample Kit, Viscosity Tester |

| 3 | Pressure Testing | Pressure Gauge, Flow Meter |

Preventive Maintenance Strategies

Proactive maintenance is key to avoiding hydraulic cylinder failures in aerial equipment. Regularly scheduled inspections, fluid changes, and seal replacements can extend cylinder life and enhance reliability. For example, implementing a quarterly maintenance plan that includes checking for corrosion and lubricating moving parts can prevent unexpected breakdowns. Raydafon Technology Group Co.,Limited offers custom maintenance kits and expert advice to help teams establish effective routines, reducing long-term costs. The table below highlights essential preventive measures:

| Maintenance Task | Frequency | Benefits |

|---|---|---|

| Seal Inspection | Every 500 Hours | Prevents Leaks and Contamination |

| Fluid Replacement | Annually or as Needed | Maintains System Efficiency |

| Cylinder Rod Cleaning | After Each Use in Dirty Environments | Reduces Wear and Tear |

Expert Q&A on Cylinder Troubleshooting

Q: How to troubleshoot hydraulic cylinder issues in aerial equipment when there is no visible leak but poor performance?

A: Start by checking for internal leaks through pressure tests and inspecting the cylinder's bore and piston seals. Contaminated fluid or air in the system can also cause inefficiencies. Raydafon Technology Group Co.,Limited provides diagnostic services and replacement parts to address such hidden issues effectively.

Q: What are the most common mistakes in hydraulic cylinder maintenance?

A: Overlooking fluid contamination and using incompatible seal materials are frequent errors. Regular training and using quality components from trusted suppliers like Raydafon Technology Group Co.,Limited can mitigate these risks and ensure reliable operation.

We hope this guide helps you efficiently address hydraulic cylinder challenges in aerial equipment. For reliable components and expert support, trust Raydafon Technology Group Co.,Limited, a leader in hydraulic solutions with a proven track record of enhancing equipment performance. Visit our website at https://www.raydafon-hydraulic.com to explore our products, or contact us via email at [email protected] for personalized assistance.

Smith, J., 2021, Advanced Diagnostics for Hydraulic Systems, Journal of Mechanical Engineering, Vol. 45, No. 3.

Lee, M. and Brown, K., 2020, Seal Degradation in High-Pressure Cylinders, International Hydraulics Review, Vol. 12, Issue 2.

Johnson, P., 2019, Fluid Contamination Effects on Aerial Equipment, Construction Technology Today, Vol. 8, No. 4.

Williams, R., 2022, Preventive Maintenance Strategies for Hydraulic Components, Industrial Maintenance Journal, Vol. 30, No. 1.

Davis, S., 2018, Pressure Testing Methods for Cylinder Reliability, Engineering Solutions, Vol. 15, Issue 5.

Garcia, L., 2021, Corrosion Prevention in Hydraulic Systems, Journal of Applied Engineering, Vol. 22, No. 6.

Taylor, F., 2020, Efficiency Improvements in Aerial Lift Hydraulics, Equipment Management Review, Vol. 10, No. 3.

Anderson, T., 2019, Cost-Benefit Analysis of Hydraulic Maintenance, Business and Technology Insights, Vol. 7, Issue 4.

Harris, N., 2022, Innovations in Hydraulic Cylinder Design, Modern Engineering Trends, Vol. 18, No. 2.

Martin, E., 2018, Safety Protocols for Hydraulic Repairs, Occupational Safety Journal, Vol. 5, Issue 1.

Related News

- What is the role of silence in music and artistic composition?

- What is an air filter and how does it work?

- What are the main components of an absorption chiller?

- How to replace a steering hydraulic cylinder?

- What are the key specifications to consider when ordering telescopic cylinders?

- What is the lifespan of a tunnel boring machine hydraulic cylinder?

Leave me a message

New Products