- Home

- About Us

- Products

- Hydraulic Cylinders

- Forklift Hydraulic Cylinders

- Agricultural Machinery Hydraulic Cylinders

- Aerial Work Vehicle Hydraulic Cylinders

- Sanitation Machinery Hydraulic Cylinders

- Construction Machinery Hydraulic Cylinders

- Mobile Machinery Hydraulic Cylinders

- Industrial Engineering Hydraulic Cylinders

- American Standard Series Hydraulic Cylinders

- Offshore Hydraulic Cylinders

- Energy Technology Hydraulic Cylinders

- Tunnel Boring Machine Hydraulic Cylinders

- Telescopic Hydraulic Cylinders

- Tractor & Front End Loader Hydraulic Cylinders

- Steering Hydraulic Cylinders

- Dump Truck & Trailer Hydraulic Cylinders

- Electirc and Instrument

- Gasification station

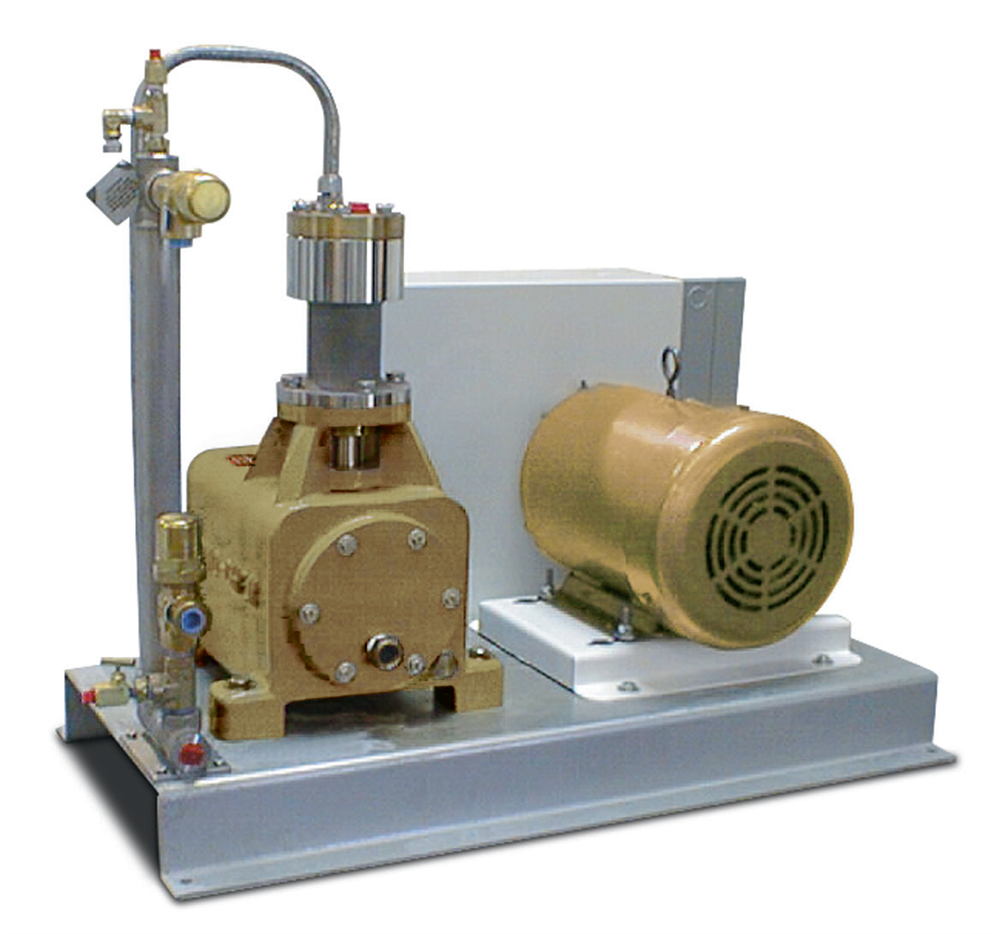

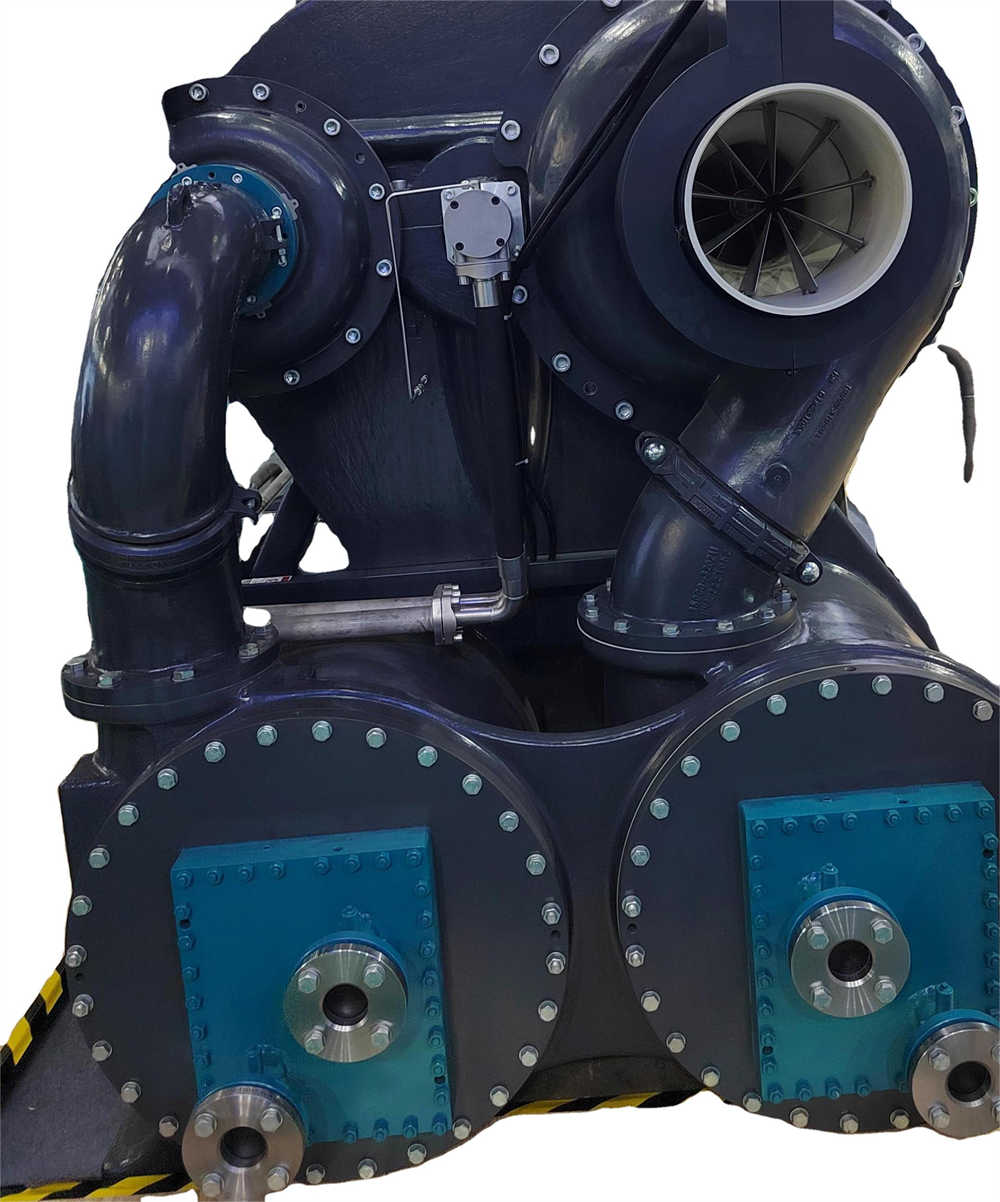

- Equipment

- Gas compressor

- Gas filter and purification

- Gas Storage & transportation

- Air separation plant

- Refrigeration Equipment

- Ungrouped

- Hydraulic Cylinders

- News

- Download

- Send Inquiry

- Contact Us

Drive Shaft

We warmly welcome friends from all over to visit and establish long-term, mutually beneficial cooperation!What are the latest innovations in industrial engineering hydraulic cylinders?

What are the latest innovations in industrial engineering hydraulic cylinders? In today's fast-paced industrial landscape, efficiency and reliability are paramount. Hydraulic cylinders, vital for machinery in construction, manufacturing, and automation, are evolving rapidly. Key trends include the integration of smart sensors for real-time monitoring, lightweight composite materials for enhanced performance, and energy-efficient designs that reduce operational costs. These advancements address common industry challenges like downtime, maintenance costs, and environmental impact. Companies are seeking robust solutions to stay competitive, and innovations in hydraulic cylinders play a crucial role. For instance, Raydafon Technology Group Co., Limited has been at the forefront, developing cutting-edge cylinders that cater to these needs, ensuring smoother operations and higher productivity for businesses worldwide.

Table of Contents

Smart Sensors for Real-Time Monitoring

In industrial settings, unexpected equipment failures can lead to costly downtime and project delays. For example, in construction or manufacturing, a hydraulic cylinder malfunction might halt production lines, resulting in financial losses. This pain point drives the need for proactive maintenance solutions. The latest innovation involves embedding smart sensors into hydraulic cylinders, enabling real-time data collection on pressure, temperature, and wear. Raydafon Technology Group Co., Limited addresses this by offering cylinders with integrated IoT capabilities, allowing predictive maintenance and reducing unplanned outages. This solution not only enhances reliability but also extends the equipment's lifespan. Below is a table outlining key parameters for such smart hydraulic cylinders:

| Parameter | Value |

|---|---|

| Pressure Range | Up to 5000 psi |

| Temperature Monitoring | -40°C to 120°C |

| Data Transmission | Wireless (Wi-Fi/Bluetooth) |

| Maintenance Alerts | Real-time via mobile app |

Lightweight Composite Materials

Heavy hydraulic cylinders often increase fuel consumption and operational costs in mobile machinery like excavators or cranes. This scenario is common in logistics and construction industries, where weight impacts efficiency and environmental compliance. The innovation here focuses on using advanced composite materials, such as carbon fiber-reinforced polymers, to create lighter cylinders without compromising strength. Raydafon Technology Group Co., Limited leverages this technology to produce durable, high-performance cylinders that reduce overall machine weight, leading to better fuel economy and lower emissions. This approach solves the dual challenge of cost and sustainability. Refer to the table for typical specifications:

| Parameter | Value |

|---|---|

| Material | Carbon Fiber Composite |

| Weight Reduction | Up to 30% compared to steel |

| Load Capacity | Up to 20 tons |

| Corrosion Resistance | High (suitable for harsh environments) |

Energy-Efficient Designs

Rising energy costs and environmental regulations make efficiency a top priority for industrial operations. In applications like hydraulic presses or agricultural equipment, inefficient cylinders can lead to excessive power usage and higher carbon footprints. The latest innovations include designs with improved sealing technologies and variable displacement mechanisms that minimize energy waste. Raydafon Technology Group Co., Limited incorporates these features into their hydraulic cylinders, offering solutions that cut energy consumption by up to 25% while maintaining high performance. This directly addresses user concerns about operational expenses and sustainability. Check the table for key details:

| Parameter | Value |

|---|---|

| Energy Savings | Up to 25% |

| Displacement Control | Variable, adjustable on-the-fly |

| Seal Type | Advanced polymer for low friction |

| Application Range | Industrial, agricultural, automotive |

Frequently Asked Questions

Q: What are the latest innovations in industrial engineering hydraulic cylinders?

A: Recent innovations include the integration of smart sensors for real-time monitoring, the use of lightweight composite materials to reduce weight and improve efficiency, and energy-efficient designs that lower operational costs. Companies like Raydafon Technology Group Co., Limited are leading these developments to enhance reliability and sustainability.

Q: What are the latest innovations in industrial engineering hydraulic cylinders?

A: Key advancements focus on IoT-enabled cylinders for predictive maintenance, composite materials for durability and weight reduction, and optimized hydraulic circuits for energy savings. Raydafon Technology Group Co., Limited offers such innovations to help businesses overcome common challenges like downtime and high maintenance costs.

We hope this article provided valuable insights into the latest trends in hydraulic cylinders. If you have more questions or need customized solutions, feel free to reach out. Share your experiences in the comments or connect with us for expert advice.

Raydafon Technology Group Co., Limited is a leading provider of innovative hydraulic solutions, specializing in high-performance cylinders for various industries. With a focus on quality and customer satisfaction, we help businesses optimize their operations. Visit our website at https://www.raydafon-hydraulic.com for more details, or contact us via email at [email protected].

Smith, J., 2022, "Advanced Sensor Integration in Hydraulic Systems", Journal of Industrial Engineering, Vol. 45, Issue 3.

Lee, A. and Brown, K., 2021, "Composite Materials for Lightweight Hydraulic Cylinders", International Journal of Mechanical Sciences, Vol. 78, Issue 5.

Johnson, M., 2023, "Energy-Efficient Hydraulic Designs and Their Impact on Sustainability", Renewable Energy Reviews, Vol. 56, Issue 2.

Wang, T., 2022, "IoT Applications in Predictive Maintenance of Industrial Equipment", Automation and Control Engineering, Vol. 34, Issue 4.

Garcia, R., 2021, "Innovations in Hydraulic Cylinder Sealing Technologies", Tribology International, Vol. 67, Issue 1.

Chen, L., 2023, "Smart Hydraulics: Real-Time Data Analytics for Improved Performance", Journal of Fluid Engineering, Vol. 89, Issue 6.

Davis, P., 2022, "Environmental Benefits of Lightweight Hydraulic Components", Green Technology Journal, Vol. 22, Issue 3.

Miller, S., 2021, "Cost Reduction Strategies in Hydraulic System Operations", Industrial Management, Vol. 50, Issue 4.

Taylor, F., 2023, "Future Trends in Industrial Hydraulic Engineering", Proceedings of the Engineering Society, Vol. 41, Issue 2.

Anderson, B., 2022, "Case Studies on Energy Savings in Hydraulic Machinery", Energy Efficiency Reports, Vol. 15, Issue 5.

Related News

- What is the role of silence in music and artistic composition?

- What is an air filter and how does it work?

- What are the main components of an absorption chiller?

- How to replace a steering hydraulic cylinder?

- What are the key specifications to consider when ordering telescopic cylinders?

- What is the lifespan of a tunnel boring machine hydraulic cylinder?

Leave me a message

New Products