- Home

- About Us

- Products

- Hydraulic Cylinders

- Forklift Hydraulic Cylinders

- Agricultural Machinery Hydraulic Cylinders

- Aerial Work Vehicle Hydraulic Cylinders

- Sanitation Machinery Hydraulic Cylinders

- Construction Machinery Hydraulic Cylinders

- Mobile Machinery Hydraulic Cylinders

- Industrial Engineering Hydraulic Cylinders

- American Standard Series Hydraulic Cylinders

- Offshore Hydraulic Cylinders

- Energy Technology Hydraulic Cylinders

- Tunnel Boring Machine Hydraulic Cylinders

- Telescopic Hydraulic Cylinders

- Tractor & Front End Loader Hydraulic Cylinders

- Steering Hydraulic Cylinders

- Dump Truck & Trailer Hydraulic Cylinders

- Electirc and Instrument

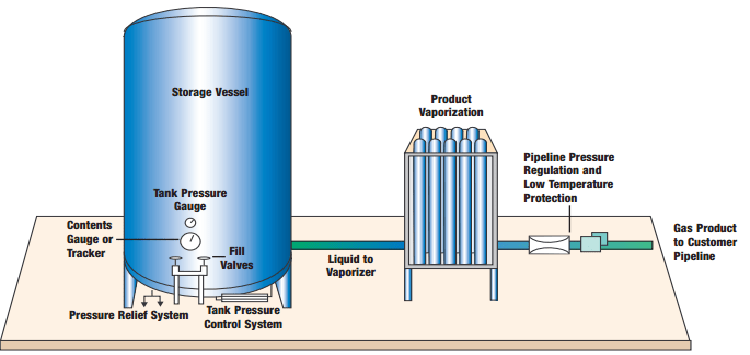

- Gasification station

- Equipment

- Gas compressor

- Gas filter and purification

- Gas Storage & transportation

- Air separation plant

- Refrigeration Equipment

- Ungrouped

- Hydraulic Cylinders

- News

- Download

- Send Inquiry

- Contact Us

Send Inquiry

Contact Info

-

Address

Luotuo Industrial Area, Zhenhai District, Ningbo City, China

-

Tel

-

E-mail