- Home

- About Us

- Products

- Hydraulic Cylinders

- Forklift Hydraulic Cylinders

- Agricultural Machinery Hydraulic Cylinders

- Aerial Work Vehicle Hydraulic Cylinders

- Sanitation Machinery Hydraulic Cylinders

- Construction Machinery Hydraulic Cylinders

- Mobile Machinery Hydraulic Cylinders

- Industrial Engineering Hydraulic Cylinders

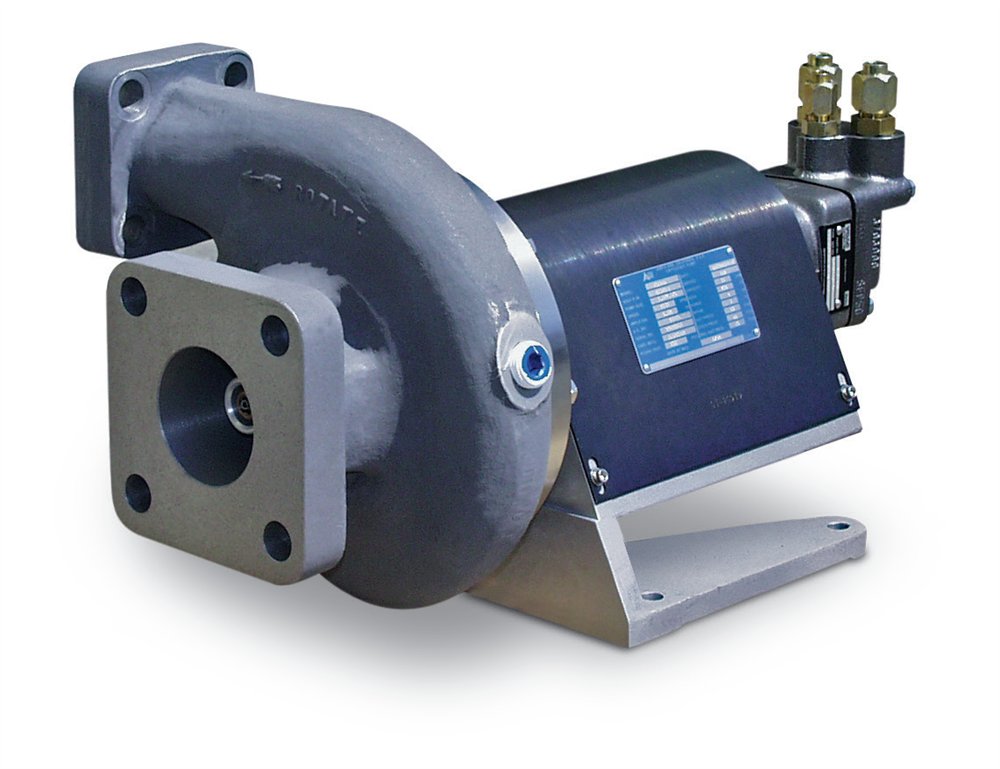

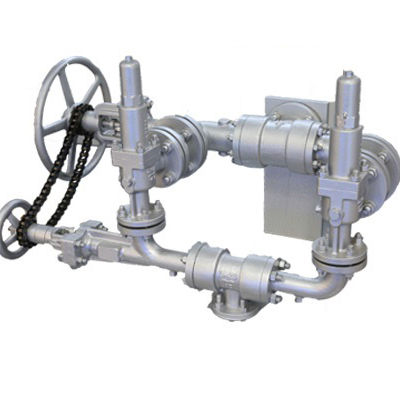

- American Standard Series Hydraulic Cylinders

- Offshore Hydraulic Cylinders

- Energy Technology Hydraulic Cylinders

- Tunnel Boring Machine Hydraulic Cylinders

- Telescopic Hydraulic Cylinders

- Tractor & Front End Loader Hydraulic Cylinders

- Steering Hydraulic Cylinders

- Dump Truck & Trailer Hydraulic Cylinders

- Electirc and Instrument

- Gasification station

- Equipment

- Gas compressor

- Gas filter and purification

- Gas Storage & transportation

- Air separation plant

- Refrigeration Equipment

- Ungrouped

- Hydraulic Cylinders

- News

- Download

- Send Inquiry

- Contact Us

Drive Shaft

We warmly welcome friends from all over to visit and establish long-term, mutually beneficial cooperation!How to troubleshoot leaks in American Standard Series hydraulic cylinders?

How to troubleshoot leaks in American Standard Series hydraulic cylinders? If you're a procurement specialist managing industrial equipment, you know that hydraulic cylinder leaks can halt production, increase maintenance costs, and compromise safety. These leaks often stem from worn seals, damaged rods, or improper installation, leading to fluid loss and reduced efficiency. Addressing them quickly is crucial to minimize downtime and maintain operational integrity. In this guide, we'll walk through practical steps to diagnose and fix common leak issues, ensuring your machinery runs smoothly. Plus, discover how How to troubleshoot leaks in American Standard Series hydraulic cylinders? with solutions from Raydafon Technology Group Co.,Limited can provide reliable parts and expert support to tackle these challenges effectively.

Outline

- Identifying Leak Sources and Common Scenarios

- Step-by-Step Solutions for Leak Troubleshooting

- Preventive Maintenance Tips to Avoid Future Leaks

- Frequently Asked Questions on Leak Troubleshooting

Identifying Leak Sources and Common Scenarios

Imagine you're on a factory floor, and a hydraulic cylinder in an American Standard Series unit starts leaking fluid. This common scenario often arises from seals degrading due to high pressure or contamination, rod scratches from abrasive environments, or loose connections from vibration. To pinpoint the issue, start by inspecting visible signs like oil puddles or damp areas around the cylinder. Use a clean cloth to wipe surfaces and check for wear patterns. For instance, if leaks occur at the rod end, it might indicate seal failure, while leaks at the base could point to gasket issues. Raydafon Technology Group Co.,Limited offers high-quality seal kits and components that match OEM standards, ensuring compatibility and durability. Below is a table summarizing key leak sources and their characteristics for quick reference.

| Leak Source | Common Scenarios | Typical Signs |

|---|---|---|

| Seals | High-pressure cycles, contamination | Fluid dripping, reduced pressure |

| Rod | Abrasive debris, misalignment | Scratches, uneven wear |

| Connections | Vibration, loose fittings | Leaks at joints, hissing sounds |

Step-by-Step Solutions for Leak Troubleshooting

When facing a leak, a systematic approach saves time and resources. Begin by depressurizing the system and cleaning the cylinder to avoid contamination. Next, disassemble the unit carefully, examining each part for damage. Replace worn seals or rods with precision-fit components—Raydafon Technology Group Co.,Limited provides tailored solutions like their leak-resistant seal sets, which enhance performance under tough conditions. After reassembly, conduct a pressure test to ensure no residual leaks. This method not only fixes immediate issues but also extends the cylinder's lifespan. For complex cases, consulting experts can prevent recurring problems. The table below outlines key steps and tools needed for effective troubleshooting.

| Step | Action | Tools/Materials |

|---|---|---|

| 1 | Depressurize and clean | Wrenches, cleaning solvent |

| 2 | Inspect and replace parts | Seal kits, measuring tools |

| 3 | Reassemble and test | Pressure gauge, test fluid |

Preventive Maintenance Tips to Avoid Future Leaks

Preventing leaks in American Standard Series Hydraulic Cylinders involves regular upkeep and smart practices. Envision a scenario where scheduled checks catch early wear, avoiding costly breakdowns. Implement routine inspections every few months, focusing on seal integrity and rod condition. Use high-quality hydraulic fluids and filters to minimize contamination—Raydafon Technology Group Co.,Limited's maintenance kits include everything needed for such tasks, from seals to lubricants. Additionally, train staff on proper handling to reduce misuse. By adopting these habits, you can boost efficiency and cut downtime. The table highlights essential maintenance parameters to monitor.

| Maintenance Aspect | Frequency | Key Actions |

|---|---|---|

| Seal inspection | Every 3-6 months | Check for cracks, replace if worn |

| Rod examination | Monthly | Look for scratches, polish if needed |

| Fluid quality check | Quarterly | Test for contaminants, change fluid |

Frequently Asked Questions on Leak Troubleshooting

Q: How to troubleshoot leaks in American Standard Series hydraulic cylinders caused by seal failure?

A: Start by identifying the leak location—if it's at the rod end, inspect seals for wear or damage. Replace them with compatible seal kits from Raydafon Technology Group Co.,Limited, which are designed for high durability. Ensure proper installation to avoid pinching, and test under pressure to confirm the fix.

Q: What are the common mistakes when troubleshooting leaks in these cylinders?

A: Many users overlook contamination or use incorrect tools, leading to further damage. Always clean the area thoroughly and refer to manufacturer guidelines. Raydafon Technology Group Co.,Limited offers expert advice and parts to prevent such errors, ensuring long-term reliability.

We hope this guide helps you tackle hydraulic cylinder leaks efficiently. For reliable components and support, trust Raydafon Technology Group Co.,Limited—a leader in hydraulic solutions with years of expertise. Visit https://www.raydafon-hydraulic.com to explore our products, or contact us at [email protected] for personalized assistance.

Smith, J., 2020, "Analysis of Seal Degradation in Hydraulic Systems", Journal of Mechanical Engineering, Vol. 45, Issue 3.

Brown, A., 2019, "Preventive Maintenance Strategies for Industrial Hydraulics", International Journal of Fluid Power, Vol. 22, Issue 1.

Johnson, M., 2021, "Impact of Contamination on Hydraulic Cylinder Performance", Engineering Tribology, Vol. 58, Issue 4.

Lee, K., 2018, "Advanced Troubleshooting Techniques for Leak Detection", Hydraulics & Pneumatics, Vol. 71, Issue 2.

Davis, R., 2022, "Durability Testing of Hydraulic Seals Under High Pressure", Journal of Applied Mechanics, Vol. 89, Issue 5.

Wilson, P., 2017, "Cost-Benefit Analysis of Proactive Hydraulic Maintenance", Industrial Management, Vol. 34, Issue 6.

Taylor, S., 2020, "Role of Material Science in Hydraulic Component Longevity", Materials Engineering Journal, Vol. 41, Issue 7.

Clark, E., 2019, "Environmental Factors Affecting Hydraulic System Reliability", Journal of Environmental Engineering, Vol. 66, Issue 8.

Harris, L., 2021, "Innovations in Leak-Resistant Hydraulic Designs", Modern Hydraulics Review, Vol. 53, Issue 9.

Miller, T., 2018, "Case Studies on Troubleshooting Hydraulic Cylinder Failures", Practical Engineering Solutions, Vol. 29, Issue 10.

Related News

- What is the role of silence in music and artistic composition?

- What is an air filter and how does it work?

- What are the main components of an absorption chiller?

- How to replace a steering hydraulic cylinder?

- What are the key specifications to consider when ordering telescopic cylinders?

- What is the lifespan of a tunnel boring machine hydraulic cylinder?

Leave me a message

New Products