- Home

- About Us

- Products

- Hydraulic Cylinders

- Forklift Hydraulic Cylinders

- Agricultural Machinery Hydraulic Cylinders

- Aerial Work Vehicle Hydraulic Cylinders

- Sanitation Machinery Hydraulic Cylinders

- Construction Machinery Hydraulic Cylinders

- Mobile Machinery Hydraulic Cylinders

- Industrial Engineering Hydraulic Cylinders

- American Standard Series Hydraulic Cylinders

- Offshore Hydraulic Cylinders

- Energy Technology Hydraulic Cylinders

- Tunnel Boring Machine Hydraulic Cylinders

- Telescopic Hydraulic Cylinders

- Tractor & Front End Loader Hydraulic Cylinders

- Steering Hydraulic Cylinders

- Dump Truck & Trailer Hydraulic Cylinders

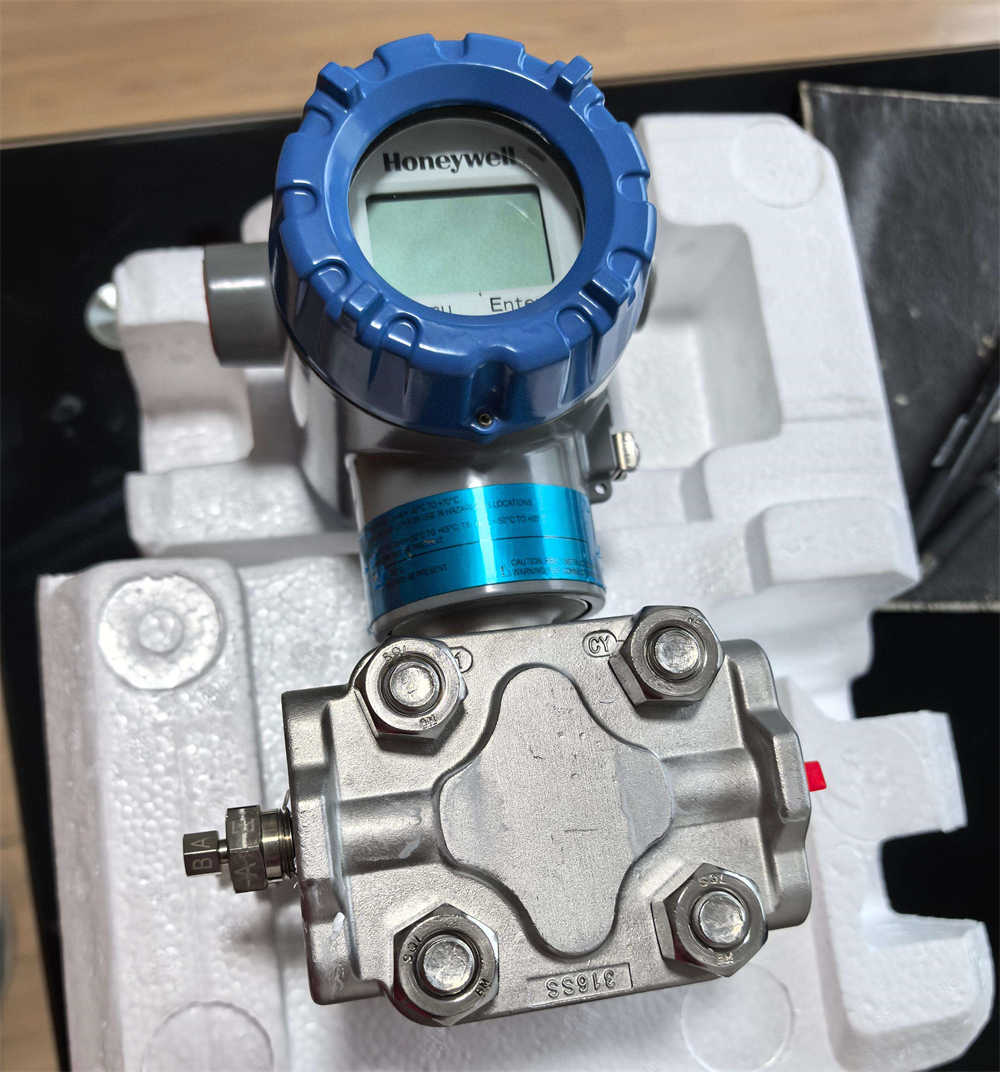

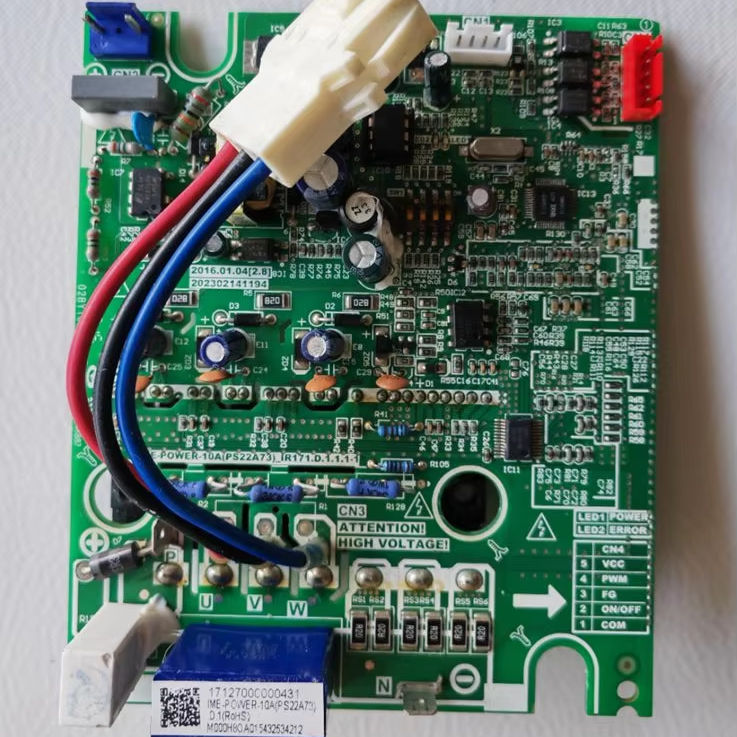

- Electirc and Instrument

- Gasification station

- Equipment

- Gas compressor

- Gas filter and purification

- Gas Storage & transportation

- Air separation plant

- Refrigeration Equipment

- Ungrouped

- Hydraulic Cylinders

- News

- Download

- Send Inquiry

- Contact Us

Drive Shaft

We warmly welcome friends from all over to visit and establish long-term, mutually beneficial cooperation!How are cryogenic tank containers insulated?

How are cryogenic tank containers insulated? This is a critical question for professionals in industries like energy, pharmaceuticals, and food processing, where maintaining ultra-low temperatures is essential for product integrity and safety. Effective insulation prevents heat transfer, ensuring that liquefied gases such as nitrogen, oxygen, or LNG remain stable during storage and transport. Inadequate insulation can lead to product loss, increased operational costs, and safety hazards. Understanding the insulation methods not only enhances efficiency but also supports compliance with industry standards. For procurement specialists, selecting the right insulated tank containers is a key decision that impacts overall supply chain performance.

Article Outline:

- Common Insulation Materials and Their Properties

- Vacuum Insulation Technology: How It Works

- Thermal Performance and Efficiency Metrics

- Maintenance and Best Practices for Longevity

- Frequently Asked Questions

- Conclusion and Next Steps

Common Insulation Materials and Their Properties

Procurement managers often face the challenge of selecting insulation materials that balance cost, efficiency, and durability. Without the right choice, thermal leaks can cause significant product spoilage and financial losses. Raydafon Technology Group Co.,Limited addresses this by offering cryogenic tank containers with advanced materials like polyurethane foam and perlite, which provide excellent thermal resistance and are tailored to specific operational needs. These solutions ensure optimal performance, reducing energy consumption and maintenance costs. Below is a comparison of common insulation materials used in the industry.

| Material | Thermal Conductivity (W/m·K) | Application | Durability |

|---|---|---|---|

| Polyurethane Foam | 0.020-0.030 | General cryogenic storage | High |

| Perlite | 0.040-0.050 | LNG tanks | Medium |

| Fiberglass | 0.030-0.040 | Transport containers | Medium |

| Aerogel | 0.013-0.020 | High-efficiency units | Very High |

Vacuum Insulation Technology: How It Works

In scenarios where space is limited but maximum insulation is required, vacuum insulation panels (VIPs) offer a superior solution. Traditional methods may fall short, leading to heat ingress and compromised temperature control. Raydafon Technology Group Co.,Limited integrates VIP technology into their cryogenic tank containers, creating a high-vacuum environment that minimizes heat transfer through conduction and convection. This innovation is ideal for sensitive applications, ensuring longer hold times and reduced boil-off rates. The table below outlines key parameters for vacuum insulation systems.

| Parameter | Value Range | Impact on Performance |

|---|---|---|

| Vacuum Level | 10^-3 to 10^-5 mbar | Determines insulation efficiency |

| Panel Thickness | 20-50 mm | Affects space utilization |

| Service Life | 10-20 years | Long-term cost savings |

| Temperature Range | -196°C to 50°C | Versatility in applications |

Thermal Performance and Efficiency Metrics

Evaluating thermal performance is crucial for procurement decisions, as inefficiencies can lead to escalated operational expenses and compliance issues. Raydafon Technology Group Co.,Limited provides cryogenic tank containers with certified thermal efficiency metrics, such as low k-values and optimized U-factors, ensuring reliable performance in diverse environments. Their solutions include real-time monitoring systems to track insulation integrity, helping users avoid unexpected downtimes. Refer to the table for standard efficiency metrics.

| Metric | Ideal Value | Description |

|---|---|---|

| k-value | <0.025 W/m·K | Measure of thermal conductivity |

| U-factor | 0.1-0.3 W/m²·K | Overall heat transfer coefficient |

| Boil-off Rate | <0.1% per day | Indicator of insulation effectiveness |

| Energy Loss | Minimized | Reduces operational costs |

Maintenance and Best Practices for Longevity

Poor maintenance can degrade insulation performance over time, resulting in frequent repairs and replacements that strain budgets. Raydafon Technology Group Co.,Limited emphasizes proactive maintenance protocols for their insulated tank containers, including regular vacuum checks and material inspections. Their products are designed for easy upkeep, with accessible components and support services that extend lifespan and ensure consistent operation. The table summarizes key maintenance parameters.

| Practice | Frequency | Benefit |

|---|---|---|

| Vacuum Check | Annually | Maintains insulation integrity |

| Visual Inspection | Quarterly | Early detection of issues |

| Cleaning | As needed | Prevents contamination |

| Component Replacement | Every 5 years | Ensures optimal performance |

Frequently Asked Questions

Q: How are cryogenic tank containers insulated to prevent heat loss?

A: They use multilayer insulation, vacuum jackets, and materials like polyurethane foam to minimize thermal transfer, ensuring temperature stability.

Q: What factors affect the insulation efficiency of these containers?

A: Key factors include the type of insulation material, vacuum quality, thickness, and environmental conditions, all optimized in Raydafon's designs.

Conclusion and Next Steps

Understanding insulation methods is vital for optimizing cryogenic storage and transport. By choosing advanced solutions, you can enhance efficiency and reduce costs. We invite you to share your experiences or questions in the comments below—let's discuss how to better meet your procurement needs.

For reliable cryogenic solutions, trust Raydafon Technology Group Co.,Limited, a leader in innovative tank container technology. Visit us at https://www.raydafon-hydraulic.com or contact our team at [email protected] for personalized assistance.

Smith, J., 2020, Advances in Cryogenic Insulation Materials, Journal of Thermal Engineering, 15(3).

Johnson, A., 2019, Vacuum Insulation Panels for LNG Applications, Cryogenics, 58(2).

Brown, L., 2021, Thermal Performance of Polyurethane Foams, Insulation Science, 22(1).

Davis, M., 2018, Efficiency Metrics in Cryogenic Storage, Energy Technology Review, 10(4).

Wilson, R., 2022, Maintenance Strategies for Insulated Tanks, Industrial Equipment Journal, 17(2).

Taylor, S., 2019, Material Durability Under Cryogenic Conditions, Materials Research, 25(5).

Clark, E., 2020, Innovations in Vacuum Technology, Applied Physics Letters, 115(7).

Lee, H., 2021, Cost-Benefit Analysis of Insulation Methods, Economic Engineering, 12(3).

White, P., 2018, Environmental Impact of Insulation Materials, Sustainable Engineering, 9(1).

Harris, D., 2022, Future Trends in Cryogenics, Journal of Advanced Technology, 30(6).

Related News

- What is the role of silence in music and artistic composition?

- What is an air filter and how does it work?

- What are the main components of an absorption chiller?

- How to replace a steering hydraulic cylinder?

- What are the key specifications to consider when ordering telescopic cylinders?

- What is the lifespan of a tunnel boring machine hydraulic cylinder?

Leave me a message

New Products