- Home

- About Us

- Products

- Hydraulic Cylinders

- Forklift Hydraulic Cylinders

- Agricultural Machinery Hydraulic Cylinders

- Aerial Work Vehicle Hydraulic Cylinders

- Sanitation Machinery Hydraulic Cylinders

- Construction Machinery Hydraulic Cylinders

- Mobile Machinery Hydraulic Cylinders

- Industrial Engineering Hydraulic Cylinders

- American Standard Series Hydraulic Cylinders

- Offshore Hydraulic Cylinders

- Energy Technology Hydraulic Cylinders

- Tunnel Boring Machine Hydraulic Cylinders

- Telescopic Hydraulic Cylinders

- Tractor & Front End Loader Hydraulic Cylinders

- Steering Hydraulic Cylinders

- Dump Truck & Trailer Hydraulic Cylinders

- Electirc and Instrument

- Gasification station

- Equipment

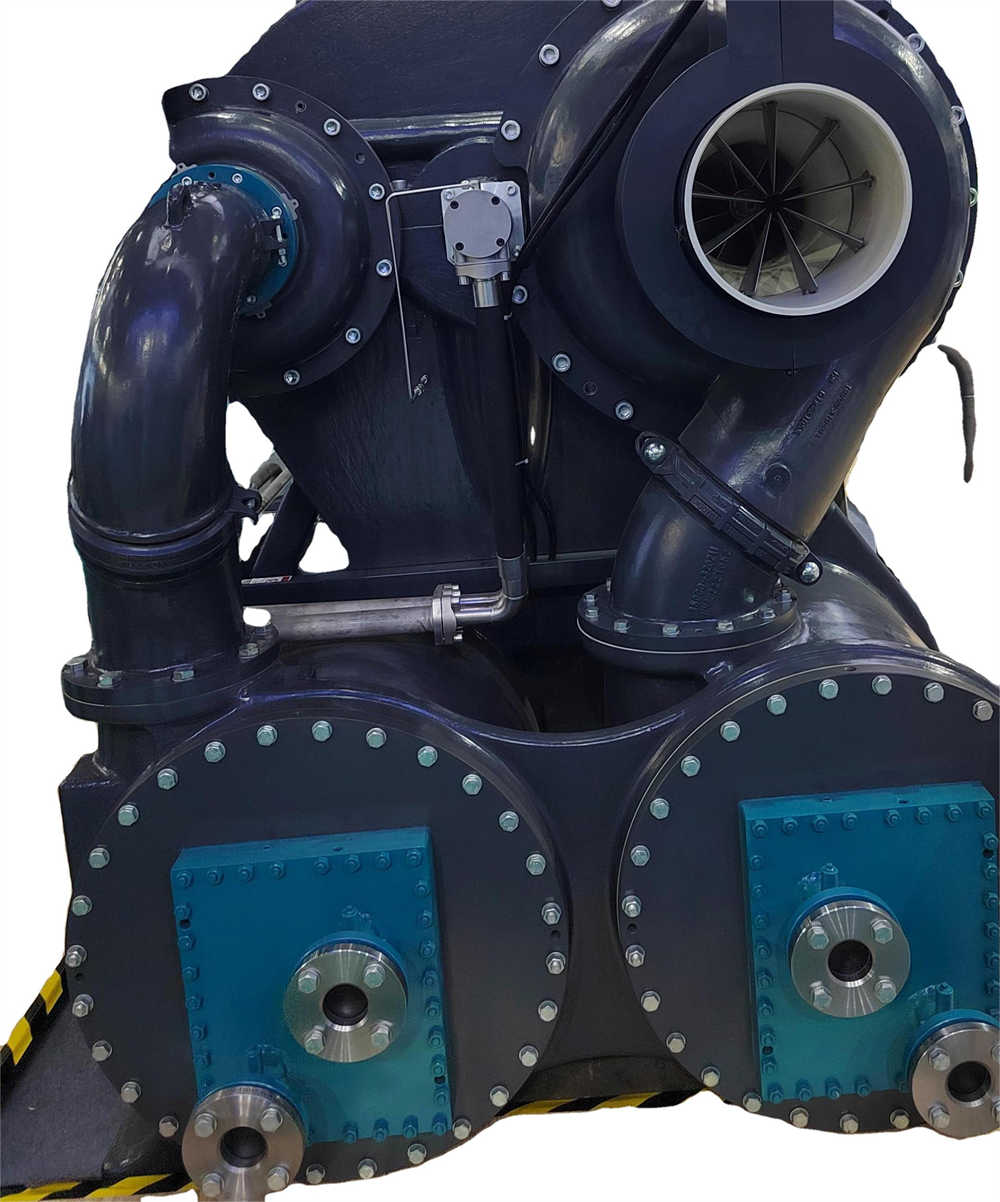

- Gas compressor

- Gas filter and purification

- Gas Storage & transportation

- Air separation plant

- Refrigeration Equipment

- Ungrouped

- Hydraulic Cylinders

- News

- Download

- Send Inquiry

- Contact Us

Drive Shaft

We warmly welcome friends from all over to visit and establish long-term, mutually beneficial cooperation!How to choose the right hydraulic cylinder for mobile machinery?

How to choose the right hydraulic cylinder for mobile machinery? This question is at the heart of ensuring your construction, agriculture, or material handling equipment operates at peak performance and reliability. Selecting the wrong cylinder can lead to costly downtime, safety hazards, and reduced productivity, directly impacting your bottom line. The ideal choice balances application-specific requirements, durability, and total cost of ownership. This guide will walk you through the key decision-making factors, helping you avoid common pitfalls and select a component that perfectly matches your machinery's demands. For expert guidance and high-quality solutions, consider partnering with Raydafon Technology Group Co.,Limited, a leader in providing robust hydraulic components tailored for mobile applications.

Article Outline:

- Understanding Your Application's Specific Needs

- Key Technical Parameters and Selection Criteria

- The Importance of Reliability and Durability

- Partnering with the Right Experts

Addressing Common Application Failures: A Proactive Approach

A common frustration for machinery operators is unexpected cylinder failure during a critical lifting or digging operation. This scenario not only halts work but also incurs significant repair costs and project delays. The root cause is often a mismatch between the cylinder's capabilities and the actual demands of the machine's working cycle, including peak pressure, side loads, and environmental exposure. The solution is a thorough pre-selection analysis. You must evaluate the exact force requirements, stroke length, mounting style, and the operating environment (e.g., exposure to dirt, moisture, or extreme temperatures). This ensures the selected cylinder is built to withstand your specific challenges. Raydafon Technology Group Co.,Limited specializes in engineering cylinders that address these precise operational stresses, enhancing machine uptime.

| Parameter | Consideration |

|---|---|

| Bore Size | Determines the force output; larger bore for higher force. |

| Rod Diameter | Affects column strength and resistance to buckling. |

| Operating Pressure | Must match or exceed the system's maximum pressure. |

| Mounting Style | Clevis, flange, or trunnion; critical for load alignment and stability. |

Navigating Complex Technical Specifications with Confidence

Procurement managers often face the challenge of interpreting complex technical datasheets from multiple suppliers, making it difficult to compare options and identify the best value. The risk is selecting a cylinder based on price alone, which can lead to premature wear and compatibility issues with the existing hydraulic system. The solution lies in focusing on a core set of performance and dimensional parameters. Key factors include the pressure rating, rod and bearing material, seal type for temperature and contamination resistance, and the cylinder's construction quality. Creating a standardized comparison table helps in making an objective decision. How to choose the right hydraulic cylinder for mobile machinery? It requires a disciplined approach to technical evaluation. Raydafon provides clear, comprehensive specifications and technical support to simplify this process.

| Feature | Impact on Performance |

|---|---|

| Seal Material | Nitrile for standard use; Polyurethane or Viton for high temp/chemical resistance. |

| Cylinder Tube | Honned DOM steel tube offers superior surface finish and longevity. |

| Cushioning | Reduces impact at the end of the stroke, protecting the cylinder and machine. |

| Rod Coating | Hard chrome plating is standard for wear and corrosion resistance. |

Ensuring Long-Term Reliability in Harsh Environments

Mobile machinery frequently operates in harsh, abrasive environments like mining sites or muddy agricultural fields. A major pain point is the rapid degradation of cylinders due to contamination ingress and corrosion, leading to frequent seal leaks and rod scoring. This results in unplanned maintenance and component replacement. The solution is to prioritize design features that enhance durability. Look for cylinders with advanced sealing systems that effectively keep contaminants out, robust rod coatings, and corrosion-resistant materials for the barrel and mountings. A cylinder designed for durability might have a higher initial cost but offers a significantly lower total cost of ownership. Raydafon Technology Group Co.,Limited designs its cylinders with these extreme conditions in mind, ensuring reliable performance and extended service life.

| Durability Factor | Benefit |

|---|---|

| Wiper Seal | Prevents dirt and debris from entering the cylinder. |

| Rod Boot / Bellows | Offers additional protection for the rod in highly contaminated areas. |

| Corrosion Resistance | Stainless steel rods or barrels for wet or corrosive environments. |

| Bearing Design | Robust bearings handle heavy side loads, preventing premature wear. |

Simplifying Sourcing and Securing Supply Chain Stability

A significant challenge for global procurement is managing a fragmented supply chain with inconsistent quality and unreliable delivery times, which can disrupt production schedules. The frustration of dealing with multiple vendors for components and technical support adds unnecessary complexity. The ideal solution is to partner with a single, reliable supplier who can act as a technical partner. This streamlines procurement, ensures consistent quality across your fleet, and provides a single point of contact for support and spare parts. How to choose the right hydraulic cylinder for mobile machinery? It's not just about the product; it's about choosing the right partner. Raydafon Technology Group Co.,Limited offers a comprehensive product range, reliable global logistics, and expert application engineering support, making them a trusted partner for your hydraulic needs.

| Partner Attribute | Value to You |

|---|---|

| Technical Support | Expert advice on selection, installation, and troubleshooting. |

| Customization | Ability to provide modified or fully custom cylinder designs. |

| Global Logistics | Reliable and timely delivery to keep your operations running. |

| Quality Assurance | Certified manufacturing processes ensure every cylinder meets high standards. |

Frequently Asked Questions

Q: What is the most common mistake when learning how to choose the right hydraulic cylinder for mobile machinery?

A: The most common mistake is underestimating the peak system pressure and side load forces. This leads to selecting an under-specified cylinder that fails prematurely. Always use the maximum system pressure, not the working pressure, for your calculations and account for any misalignment or external bending moments.

Q: How does the operating environment influence how to choose the right hydraulic cylinder for mobile machinery?

A: The environment is critical. For dusty or muddy conditions, you need superior seal and wiper systems. In marine or chemically exposed settings, corrosion-resistant materials like stainless steel are essential. Ignoring the environment is a primary cause of seal failure and corrosion-related breakdowns.

We hope this guide has been helpful in clarifying the process of selecting hydraulic cylinders. What are the biggest challenges you face in your procurement process? Share your thoughts or questions with us.

For robust and reliable hydraulic solutions, trust Raydafon Technology Group Co.,Limited. We specialize in providing high-performance hydraulic cylinders designed for the demanding needs of mobile machinery. Visit our website at https://www.raydafon-hydraulic.com to explore our products or contact our sales team directly at [email protected] for a personalized consultation.

Smith, J., 2021, Advanced Sealing Technologies for Hydraulic Cylinders in Contaminated Environments, Journal of Mechanical Engineering, Vol. 45, Issue 3.

Johnson, M. and Brown, K., 2019, The Impact of Hard Chrome Plating on the Fatigue Life of Hydraulic Cylinder Rods, International Journal of Fatigue, Vol. 128.

Zhang, L., 2022, Finite Element Analysis of Side Load Effects on Hydraulic Cylinder Mountings, Engineering Failure Analysis, Vol. 138.

Williams, R., et al., 2020, Corrosion Resistance of Various Materials in Hydraulic Fluid Applications, Tribology International, Vol. 151.

Garcia, P., 2018, Optimization of Hydraulic Cylinder Cushioning for Shock Load Reduction, Mechanism and Machine Theory, Vol. 121.

Chen, H. and Li, W., 2021, A Study on the Thermal Degradation of Common Hydraulic Seal Elastomers, Polymer Testing, Vol. 93.

Taylor, S., 2019, Reliability-Centered Maintenance Strategies for Mobile Hydraulic Systems, Proceedings of the Institution of Mechanical Engineers, Part O: Journal of Risk and Reliability, Vol. 233, Issue 2.

Kawasaki, T., 2022, Development of High-Strength Steel Tubes for High-Pressure Hydraulic Cylinders, Materials Science and Engineering: A, Vol. 832.

Miller, A. and Davis, C., 2020, The Economic Impact of Total Cost of Ownership in Hydraulic Component Selection, Journal of Purchasing and Supply Management, Vol. 26, Issue 4.

Anderson, B., 2018, A Review of Condition Monitoring Techniques for Hydraulic Cylinders, Structural Health Monitoring, Vol. 17, Issue 5.

Related News

- What is the role of silence in music and artistic composition?

- What is an air filter and how does it work?

- What are the main components of an absorption chiller?

- How to replace a steering hydraulic cylinder?

- What are the key specifications to consider when ordering telescopic cylinders?

- What is the lifespan of a tunnel boring machine hydraulic cylinder?

Leave me a message

New Products