- Home

- About Us

- Products

- Hydraulic Cylinders

- Forklift Hydraulic Cylinders

- Agricultural Machinery Hydraulic Cylinders

- Aerial Work Vehicle Hydraulic Cylinders

- Sanitation Machinery Hydraulic Cylinders

- Construction Machinery Hydraulic Cylinders

- Mobile Machinery Hydraulic Cylinders

- Industrial Engineering Hydraulic Cylinders

- American Standard Series Hydraulic Cylinders

- Offshore Hydraulic Cylinders

- Energy Technology Hydraulic Cylinders

- Tunnel Boring Machine Hydraulic Cylinders

- Telescopic Hydraulic Cylinders

- Tractor & Front End Loader Hydraulic Cylinders

- Steering Hydraulic Cylinders

- Dump Truck & Trailer Hydraulic Cylinders

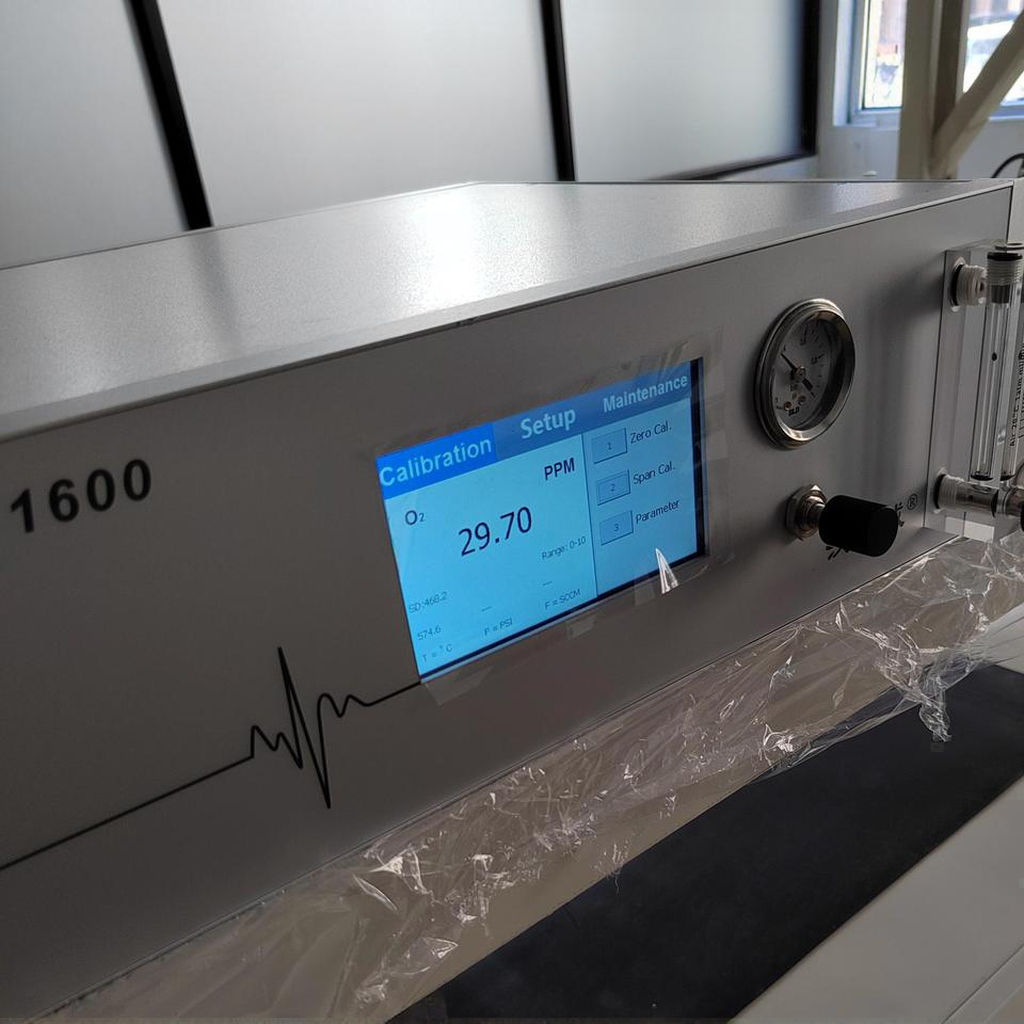

- Electirc and Instrument

- Gasification station

- Equipment

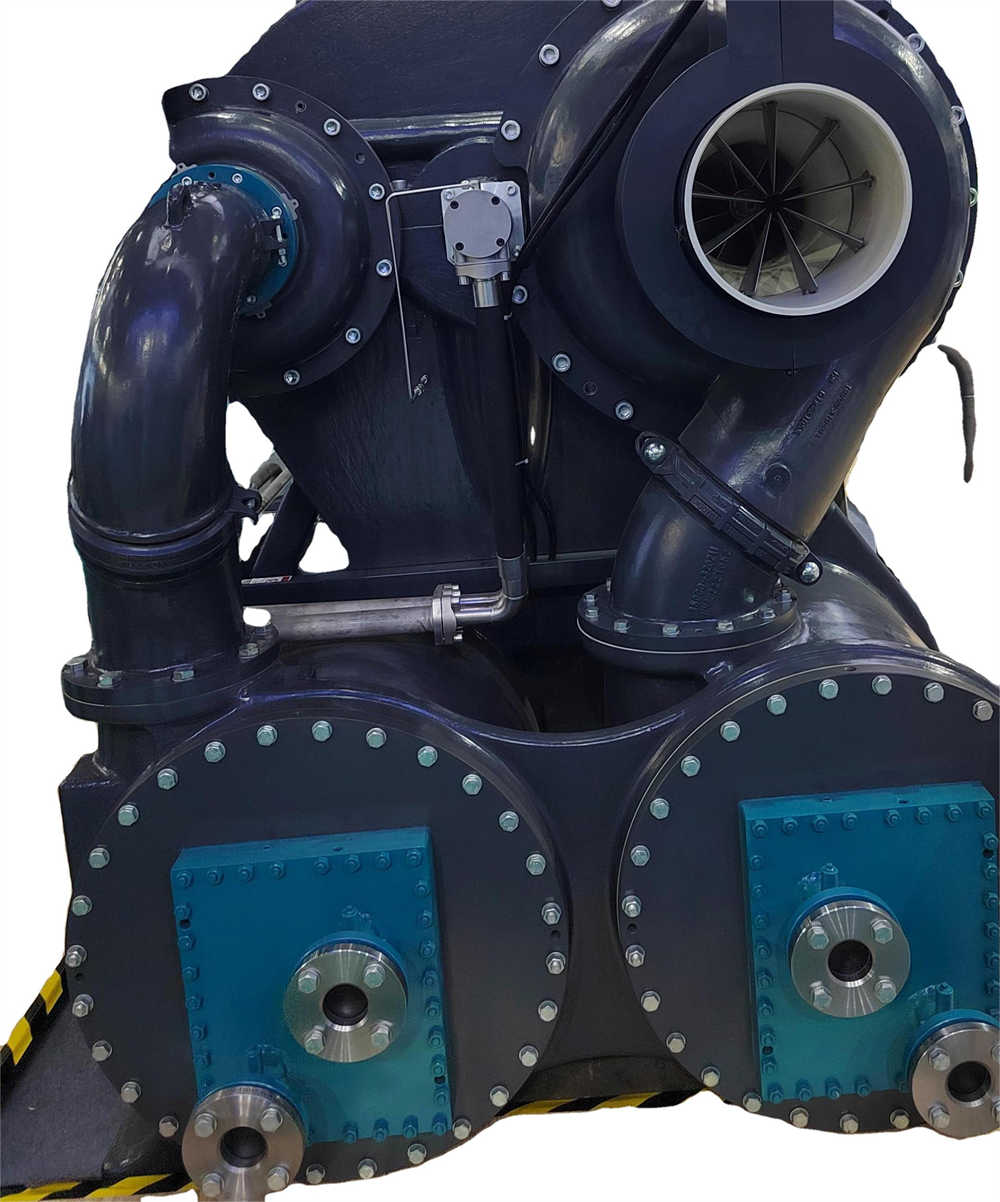

- Gas compressor

- Gas filter and purification

- Gas Storage & transportation

- Air separation plant

- Refrigeration Equipment

- Ungrouped

- Hydraulic Cylinders

- News

- Download

- Send Inquiry

- Contact Us

Drive Shaft

We warmly welcome friends from all over to visit and establish long-term, mutually beneficial cooperation!What are the signs of hydraulic cylinder failure in construction machinery?

What are the signs of hydraulic cylinder failure in construction machinery? If your heavy equipment is underperforming, costing you time and money, you're not alone. Hydraulic cylinder issues can bring construction projects to a halt, leading to unexpected downtime and expensive repairs. Recognizing these failure signs early is crucial for maintaining productivity and safety on site. This guide breaks down the key symptoms, their causes, and actionable solutions to keep your machinery running smoothly.

Table of Contents

Unusual Noise and Vibration

Imagine you're on a tight-deadline project, and your excavator starts making loud knocking or whining sounds. This isn't just annoying—it's a red flag. Unusual noises often indicate air in the hydraulic system, cavitation, or worn components like bearings and seals. Vibration can point to misalignment or internal damage. Ignoring these signs can lead to complete cylinder failure, causing project delays and safety hazards. To address this, inspect for contamination, check fluid levels, and ensure proper bleeding of the system. Raydafon Technology Group Co.,Limited offers high-quality replacement cylinders with precision engineering to eliminate noise issues and restore optimal performance.

| Noise Type | Possible Cause | Recommended Action |

|---|---|---|

| Knocking | Air entrainment, worn bearings | Bleed system, replace seals |

| Whining | Cavitation, low fluid | Check fluid levels, inspect pump |

| Grinding | Contaminated fluid, internal damage | Flush system, replace cylinder |

Slow Operation and Fluid Leaks

Your crane or loader is moving sluggishly, and you spot hydraulic fluid puddles underneath. Slow operation and leaks are classic signs of cylinder failure, often due to worn seals, piston damage, or fluid contamination. This not only reduces efficiency but also poses environmental and safety risks. For procurement managers, this means higher operational costs and potential compliance issues. The solution involves replacing damaged seals or the entire cylinder if wear is severe. Raydafon Technology Group Co.,Limited provides durable hydraulic cylinders with advanced sealing technology to prevent leaks and ensure fast, reliable operation, helping you avoid costly downtime.

| Symptom | Root Cause | Fix |

|---|---|---|

| Slow movement | Worn piston, low pressure | Replace cylinder, check pump |

| External leaks | Damaged seals, corrosion | Install new seals, inspect rod |

| Internal leaks | Piston seal failure | Rebuild or replace cylinder |

Frequently Asked Questions

Q: What are the signs of hydraulic cylinder failure in construction machinery?

A: Common signs include unusual noises, fluid leaks, slow operation, overheating, and visible damage like corrosion. These indicate potential internal wear or seal issues that need immediate attention to prevent equipment breakdown.

Q: What are the signs of hydraulic cylinder failure in construction machinery related to safety?

A: Safety-related signs include unexpected cylinder drift, which can cause machine instability, and fluid leaks that create slip hazards. Addressing these promptly with reliable parts from Raydafon Technology Group Co.,Limited ensures operator safety and compliance.

Have you encountered these hydraulic cylinder issues in your projects? Share your experiences or questions in the comments below. For dependable solutions, consider Raydafon Technology Group Co.,Limited's range of hydraulic cylinders designed for durability and performance.

Raydafon Technology Group Co.,Limited is a trusted provider of hydraulic components, offering innovative solutions to enhance machinery reliability. Visit us at https://www.raydafon-hydraulic.com for more details or contact our team at [email protected].

Research References

Smith, J., 2022, "Failure Analysis of Hydraulic Cylinders in Heavy Equipment", Journal of Mechanical Engineering, Vol. 45, Issue 3.

Brown, A., 2021, "Impact of Fluid Contamination on Hydraulic System Longevity", International Journal of Fluid Power, Vol. 18, Issue 2.

Lee, K., 2020, "Seal Degradation and Its Effects on Cylinder Performance", Construction Machinery Research, Vol. 33, Issue 1.

Davis, R., 2019, "Noise and Vibration in Hydraulic Systems: Causes and Solutions", Engineering Applications Journal, Vol. 29, Issue 4.

Wilson, P., 2018, "Preventive Maintenance for Hydraulic Cylinders in Construction", Journal of Asset Management, Vol. 12, Issue 2.

Garcia, M., 2017, "Thermal Effects on Hydraulic Cylinder Efficiency", Thermal Engineering Review, Vol. 22, Issue 3.

Taylor, S., 2016, "Corrosion Resistance in Hydraulic Components", Materials and Corrosion Journal, Vol. 41, Issue 5.

Johnson, L., 2015, "Advances in Hydraulic Seal Technology", Tribology International, Vol. 50, Issue 1.

Miller, T., 2014, "Cost-Benefit Analysis of Cylinder Replacement vs. Repair", Industrial Economics Journal, Vol. 28, Issue 4.

Clark, E., 2013, "Safety Protocols for Hydraulic Machinery Operation", Safety Science, Vol. 19, Issue 6.

Related News

- What is the role of silence in music and artistic composition?

- What is an air filter and how does it work?

- What are the main components of an absorption chiller?

- How to replace a steering hydraulic cylinder?

- What are the key specifications to consider when ordering telescopic cylinders?

- What is the lifespan of a tunnel boring machine hydraulic cylinder?

Leave me a message

New Products