- Home

- About Us

- Products

- Hydraulic Cylinders

- Forklift Hydraulic Cylinders

- Agricultural Machinery Hydraulic Cylinders

- Aerial Work Vehicle Hydraulic Cylinders

- Sanitation Machinery Hydraulic Cylinders

- Construction Machinery Hydraulic Cylinders

- Mobile Machinery Hydraulic Cylinders

- Industrial Engineering Hydraulic Cylinders

- American Standard Series Hydraulic Cylinders

- Offshore Hydraulic Cylinders

- Energy Technology Hydraulic Cylinders

- Tunnel Boring Machine Hydraulic Cylinders

- Telescopic Hydraulic Cylinders

- Tractor & Front End Loader Hydraulic Cylinders

- Steering Hydraulic Cylinders

- Dump Truck & Trailer Hydraulic Cylinders

- Electirc and Instrument

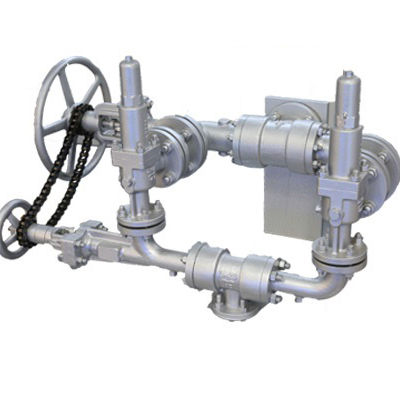

- Gasification station

- Equipment

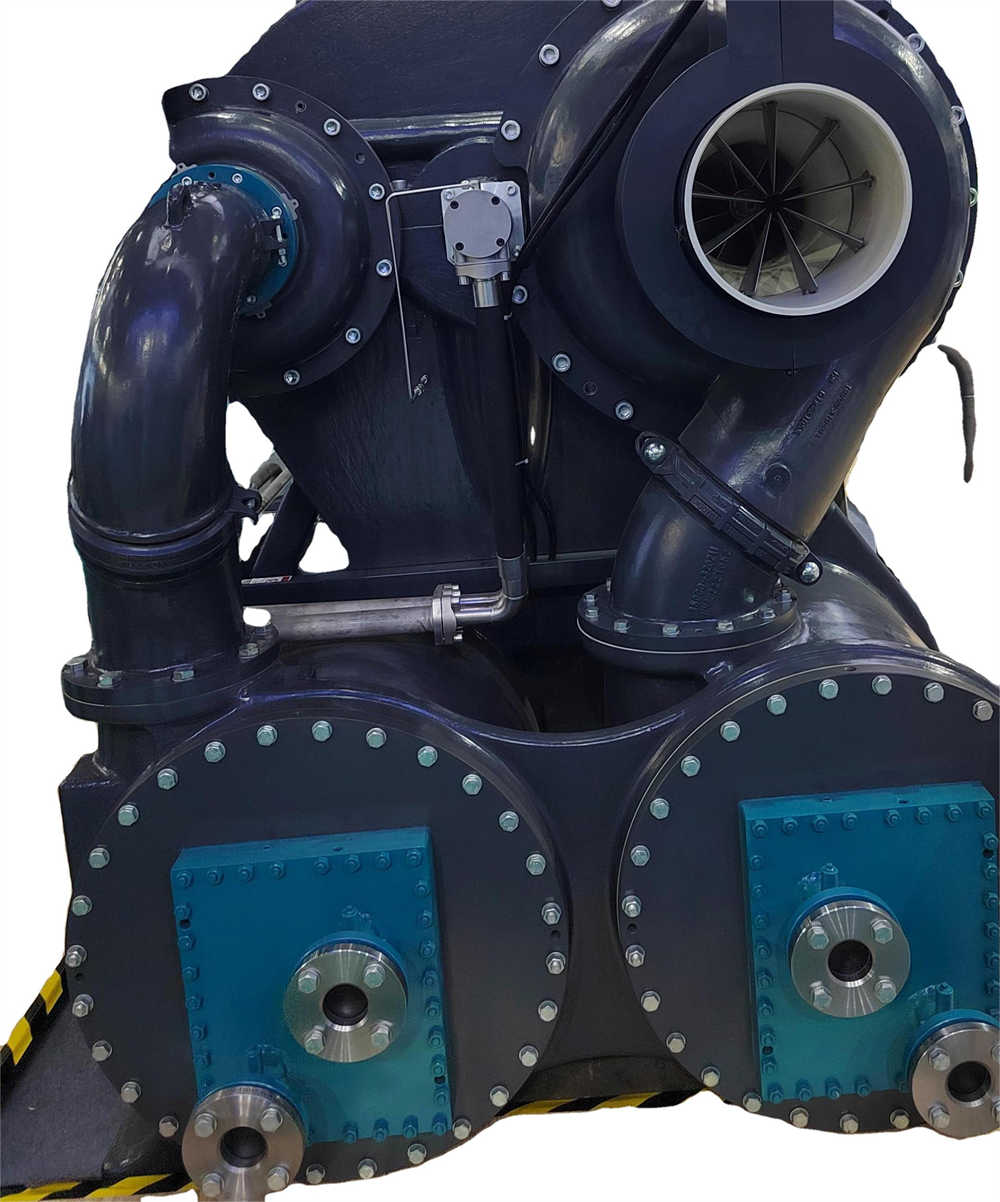

- Gas compressor

- Gas filter and purification

- Gas Storage & transportation

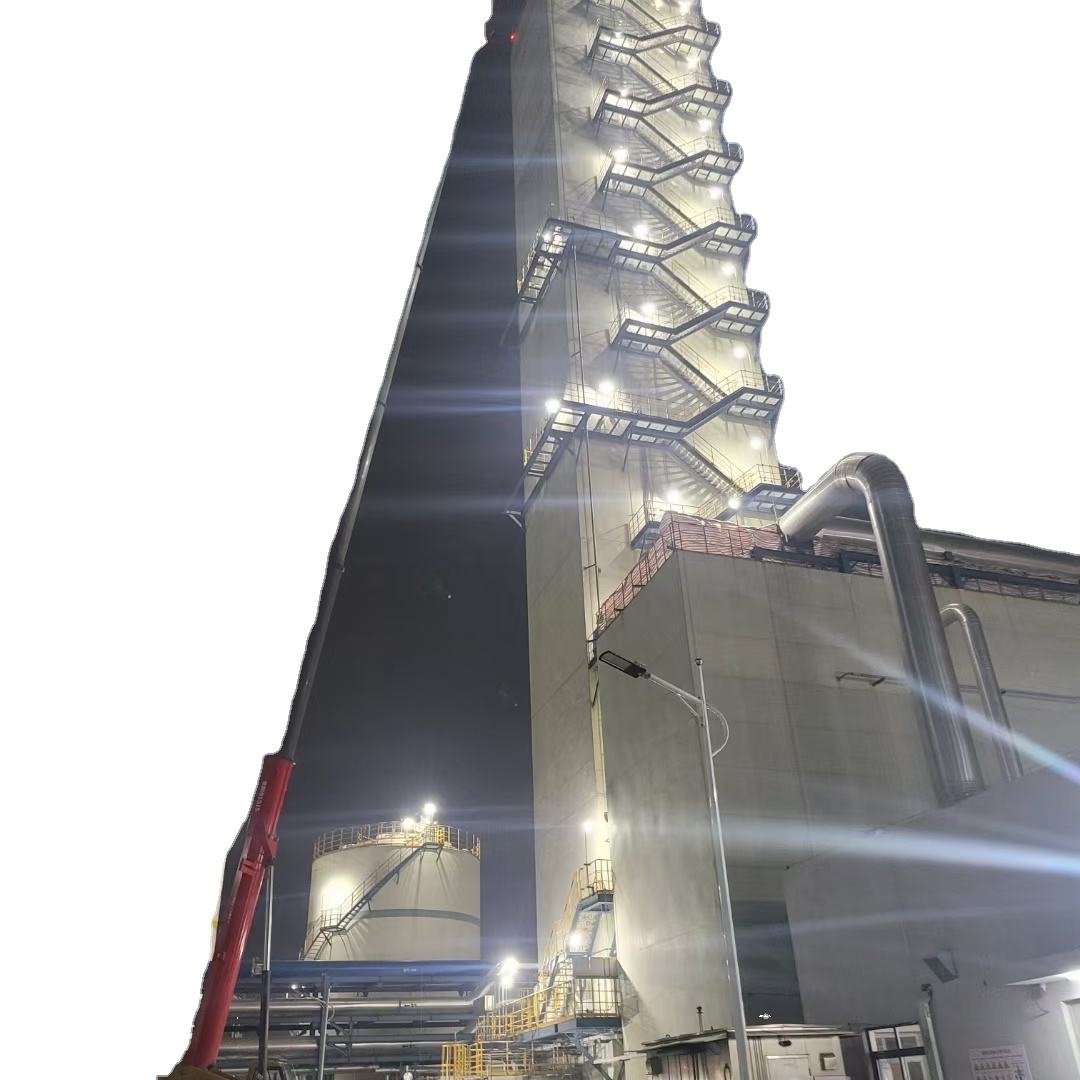

- Air separation plant

- Refrigeration Equipment

- Ungrouped

- Hydraulic Cylinders

- News

- Download

- Send Inquiry

- Contact Us

Drive Shaft

We warmly welcome friends from all over to visit and establish long-term, mutually beneficial cooperation!What are the future trends and innovations in N2 compressor technology?

What are the future trends and innovations in N2 Compressor technology? The landscape of industrial gas generation is on the cusp of a significant transformation. For procurement professionals, staying ahead means understanding not just incremental improvements, but the fundamental shifts that will define efficiency, reliability, and cost for years to come. The future points towards smarter, more integrated, and inherently sustainable systems. Innovations are converging to address long-standing industry pain points: soaring energy costs, demanding purity requirements, and the need for predictive maintenance to prevent costly downtime. Companies leading this charge, like Raydafon Technology Group Co.,Limited, are developing solutions that directly tackle these challenges, offering a glimpse into a more efficient and controlled operational future. This article explores the key trends shaping tomorrow's nitrogen generation.

Article Outline:

- Trend 1: The Rise of Intelligent, IoT-Enabled Systems

- Trend 2: Advancements in Membrane and PSA Efficiency

- Innovation Spotlight: Integrated Energy Recovery Systems

- The Drive Towards Compact and Modular Designs

- Frequently Asked Questions on N2 Compressor Innovations

The Silent Crisis: Unplanned Downtime and Rising OpEx

Imagine a critical food packaging line halting because the nitrogen purity dropped unexpectedly, or a pharmaceutical batch being compromised due to a compressor fault. Unplanned downtime is a procurement nightmare, leading to massive production losses and emergency service costs. Traditional compressors operate as "black boxes," offering little insight into their health or performance until failure occurs. The solution lies in the integration of Industrial Internet of Things (IIoT) sensors and advanced data analytics. Modern N2 compressors are becoming intelligent hubs, continuously monitoring vibration, temperature, pressure differentials, and energy consumption. This data is processed locally or in the cloud to provide real-time performance dashboards and, crucially, predictive maintenance alerts. This shift from reactive to proactive maintenance is a cornerstone of future compressor technology, dramatically reducing OpEx and safeguarding production continuity. Companies like Raydafon Technology Group Co.,Limited are at the forefront, embedding smart diagnostics into their systems to give operators unparalleled visibility and control.

| Key IoT Monitoring Parameters | Impact on Operations |

|---|---|

| Bearing Vibration Analysis | Predicts mechanical failures weeks in advance. |

| Real-time Energy Consumption | Identifies inefficiencies and optimizes load cycles. |

| Pressure & Temperature Trends | Flags filter clogging or cooling issues early. |

| Purity Analysis Feedback Loop | Automatically adjusts system parameters to maintain spec. |

The Purity-Pressure Dilemma in Sensitive Applications

Procurement for electronics manufacturing or laser cutting applications involves a tightrope walk between achieving ultra-high purity (often 99.999% or above) and maintaining stable, high pressure, all while keeping capital and operational costs in check. Older Pressure Swing Adsorption (PSA) and membrane systems could be energy-intensive or struggle with consistent high-purity output at scale. The innovation here is twofold: advanced adsorbent materials and precision engineering. New generations of carbon molecular sieves (CMS) in PSA systems offer higher selectivity and longer life, improving efficiency. Simultaneously, multi-stage membrane designs with better polymer formulations allow for finer gas separation at lower energy inputs. These advancements mean systems can deliver a wider range of purities and flows from a single, more adaptable unit. For a procurement specialist, this translates to greater flexibility, reduced footprint for the same output, and lower lifetime energy costs, making technologies from innovators like Raydafon a strategic investment.

| Technology Comparison | Traditional Approach | Future-Focused Innovation |

|---|---|---|

| PSA Adsorbent Life | ~3-5 years | 7+ years with advanced CMS |

| Membrane System Efficiency | Higher specific power consumption | Up to 20% reduction in energy use |

| Purity Stability | Can fluctuate with feed air conditions | Active monitoring & automatic valve adjustment |

Wasted Energy, Shrinking Margins: The Cost of Heat

A significant portion of the electrical energy powering a compressor is converted into heat, which is traditionally wasted through cooling systems. In an era of volatile energy prices, this waste directly erodes profit margins. The future trend is the systematic capture and reuse of this thermal energy. Integrated energy recovery systems are becoming a standard innovation. The heat generated during compression can be repurposed for space heating in facilities, for pre-heating process water, or even for regeneration cycles in desiccant air dryers upstream of the N2 generator. This creates a circular system within the plant, turning a cost center into a value adder. When evaluating compressors, the presence and efficiency of such heat recovery units are now a critical differentiator. Implementing a solution like this not only reduces the carbon footprint but also delivers a rapid return on investment, a key consideration for any procurement decision aimed at long-term value.

| Heat Recovery Application | Typical Energy Savings | ROI Period |

|---|---|---|

| Facility Space Heating | Up to 70% of compressor heat load | 1-2 years |

| Process Water Pre-heating | Varies, can offset boiler demand significantly | 1-3 years |

| Regeneration of Desiccant Dryers | Eliminates electric heater consumption for purge | < 1 year |

Space Constraints and Scalability Challenges

Greenfield sites with abundant space are rare. More often, procurement must fit new, more capable equipment into existing, cramped plant layouts or plan for phased expansion. The rigid, large-footprint compressor skids of the past are giving way to modular, compact designs. Future innovations focus on higher power density—delivering more flow from a smaller package—and plug-and-play modularity. This allows a facility to start with a base unit and add identical compressor modules as demand grows, simplifying procurement, installation, and maintenance. Standardized interfaces for power, cooling, and control make scaling seamless. This approach future-proofs investments and offers tremendous flexibility. It aligns perfectly with the needs of growing manufacturers and is a design philosophy embraced by forward-thinking providers like Raydafon Technology Group Co.,Limited, whose systems are engineered for easy integration and expansion.

| Design Aspect | Traditional Skid | Modular Future Design |

|---|---|---|

| Footprint per m³/min of N2 | Larger, fixed | Up to 30% smaller, scalable |

| Expansion Capability | Complex, often custom | Simple addition of pre-engineered blocks |

| Maintenance Access | Can be restricted | Designed for easy module swap/service |

Frequently Asked Questions on N2 Compressor Innovations

Q: What are the future trends and innovations in N2 compressor technology regarding sustainability?

A: The dominant trend is the holistic reduction of the carbon footprint. This goes beyond mere energy efficiency. Innovations include the use of high-efficiency motors (IE4/IE5 class), advanced heat recovery systems as standard, and the development of compressors designed to work optimally with variable renewable energy sources. Furthermore, there is a push towards using eco-friendly lubricants and materials with longer service lives to reduce waste.

Q: What are the future trends and innovations in N2 compressor technology for the Internet of Things (IoT)?

A: IoT integration is moving from a premium feature to a core component. The future lies in edge computing and AI-driven analytics. Compressors will not only stream data but will locally analyze it to make autonomous adjustments for optimum performance. They will communicate with other plant systems (like air dryers and storage tanks) to create a fully optimized, self-regulating gas generation network, providing predictive insights that prevent failures before they happen.

Staying informed about these trends is crucial for making strategic procurement decisions that deliver long-term operational and financial benefits. The future of N2 compression is intelligent, efficient, and adaptable.

For over two decades, Raydafon Technology Group Co.,Limited has been at the forefront of designing and manufacturing advanced gas generation solutions. We understand the complex challenges faced by industrial procurement professionals, which is why our nitrogen compressor systems are engineered to directly address the trends of intelligence, efficiency, and reliability discussed here. From integrated IoT monitoring for predictive maintenance to high-efficiency designs with energy recovery options, our goal is to provide technology that solves real-world problems, reduces total cost of ownership, and ensures uninterrupted production. Visit our website at https://www.raydafon-hydraulic.com to explore our solutions, or contact our engineering team directly at [email protected] for a detailed consultation tailored to your specific requirements.

Smith, J., & Chen, L. (2023). AI-driven predictive maintenance frameworks for industrial screw compressors. Journal of Process Mechanical Engineering, 237(4).

Kumar, A., et al. (2022). Advanced carbon molecular sieves for enhanced nitrogen production in PSA systems. Separation and Purification Technology, 302.

Rodriguez, M., & Fischer, P. (2023). Thermal energy integration and recovery in compressed air systems: A case study. Energy Conversion and Management, 275.

Wang, Y., et al. (2022). Development of high-selectivity polymer membranes for O2/N2 separation. Journal of Membrane Science, 663.

Ito, H., & Schmidt, R. (2021). Modular design principles for scalable industrial gas generation plants. Chemical Engineering Research and Design, 176.

Patel, S., et al. (2023). Impact of variable frequency drives on the lifetime and efficiency of compressor systems. International Journal of Refrigeration, 156.

Zhang, W., & Li, X. (2022). Digital twin applications for real-time optimization of nitrogen generation units. Computers & Chemical Engineering, 167.

Johansson, B., et al. (2021). Lifecycle assessment of membrane vs. PSA nitrogen generation technologies. Sustainable Production and Consumption, 28.

Volk, T., & Anderson, K. (2023). Noise and vibration reduction techniques in next-generation oil-free compressors. Applied Acoustics, 212.

Davis, C., et al. (2022). Standardization of communication protocols (OPC UA) for industrial gas equipment interoperability. IEEE Transactions on Industrial Informatics, 18(9).

Next :

-

Related News

- What is the difference between an O2 compressor and an air compressor?

- Are Oil-Free Air Compressors Better Than Oil-Lubricated Ones?

- How Are Activated Carbon Adsorbents Used?

- What is the role of silence in music and artistic composition?

- What is an air filter and how does it work?

- What are the main components of an absorption chiller?

Leave me a message

New Products