- Home

- About Us

- Products

- Hydraulic Cylinders

- Forklift Hydraulic Cylinders

- Agricultural Machinery Hydraulic Cylinders

- Aerial Work Vehicle Hydraulic Cylinders

- Sanitation Machinery Hydraulic Cylinders

- Construction Machinery Hydraulic Cylinders

- Mobile Machinery Hydraulic Cylinders

- Industrial Engineering Hydraulic Cylinders

- American Standard Series Hydraulic Cylinders

- Offshore Hydraulic Cylinders

- Energy Technology Hydraulic Cylinders

- Tunnel Boring Machine Hydraulic Cylinders

- Telescopic Hydraulic Cylinders

- Tractor & Front End Loader Hydraulic Cylinders

- Steering Hydraulic Cylinders

- Dump Truck & Trailer Hydraulic Cylinders

- Electirc and Instrument

- Gasification station

- Equipment

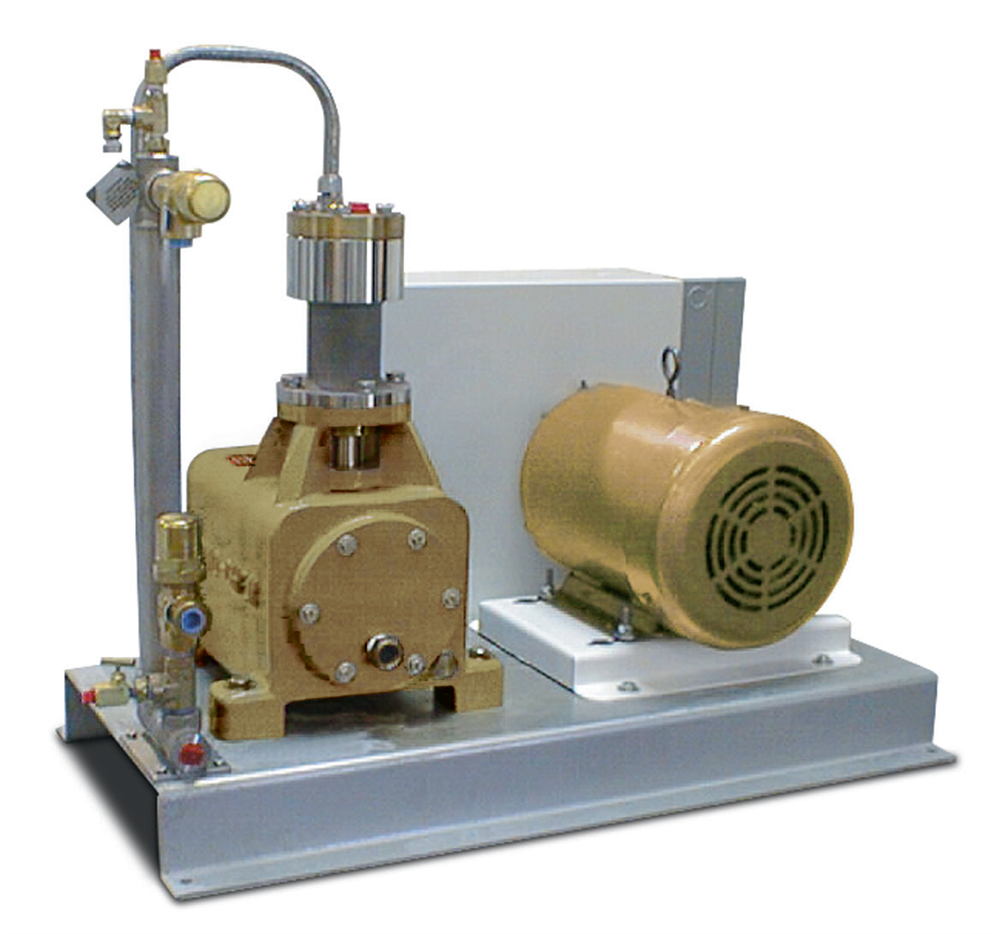

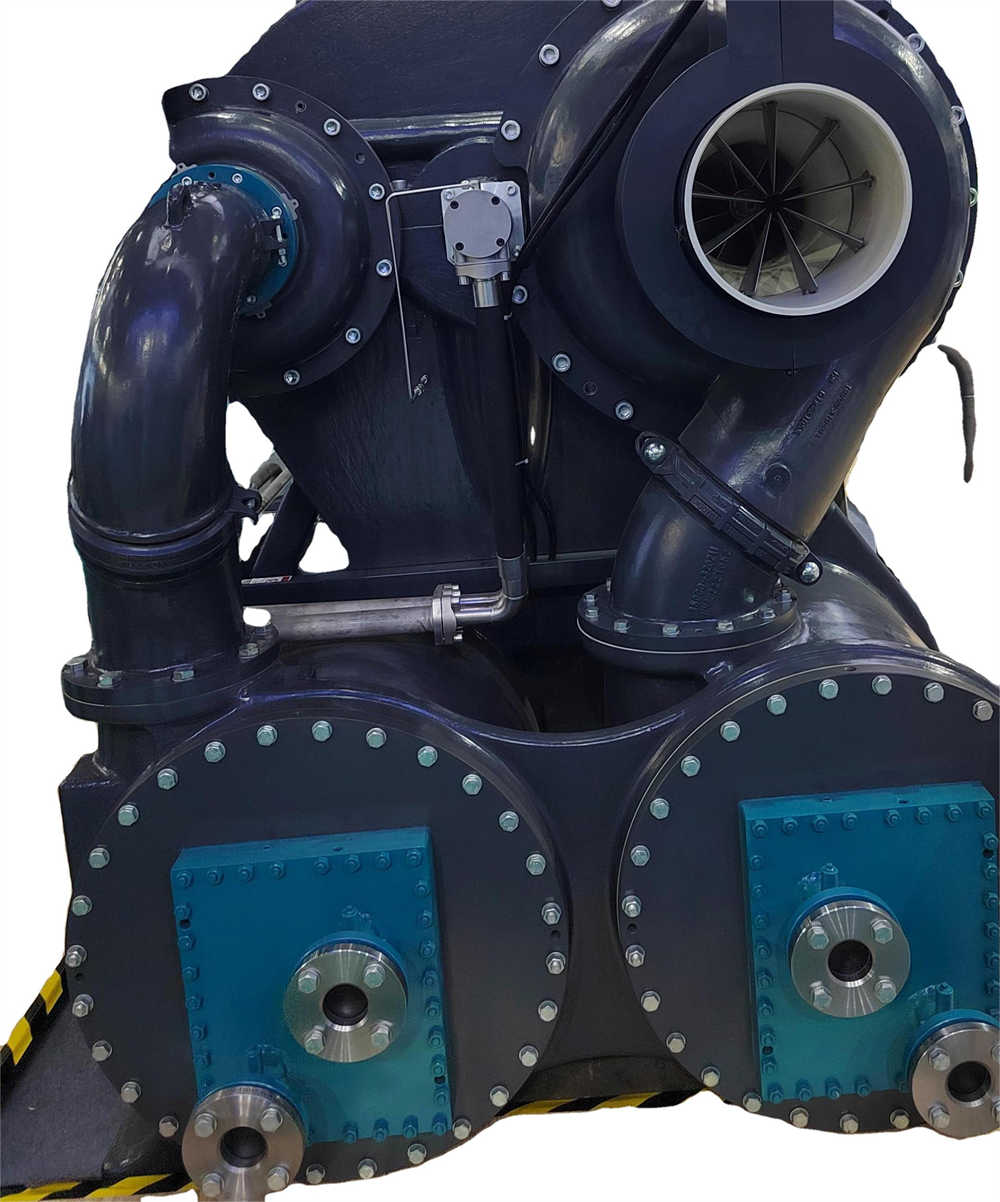

- Gas compressor

- Gas filter and purification

- Gas Storage & transportation

- Air separation plant

- Refrigeration Equipment

- Ungrouped

- Hydraulic Cylinders

- News

- Download

- Send Inquiry

- Contact Us

Drive Shaft

We warmly welcome friends from all over to visit and establish long-term, mutually beneficial cooperation!How to Choose the Right Telescopic Hydraulic Cylinder for Your Application?

How to Choose the Right Telescopic Hydraulic Cylinder for Your Application? Selecting the ideal telescopic hydraulic cylinder is crucial for industrial operations, yet many procurement specialists face challenges in matching specifications with real-world demands. Imagine you're working on a heavy-duty construction project or a material handling system, and you need a cylinder that delivers consistent power, reliability, and efficient performance under high loads. Without the right choice, you risk operational delays, increased maintenance costs, and safety hazards. This guide simplifies the process by breaking down key factors like load capacity, stroke length, and mounting styles. For instance, Raydafon Technology Group Co.,Limited offers tailored solutions to help you navigate these decisions, ensuring you get a cylinder that fits perfectly into your application and boosts productivity. Let's dive into the essential steps to make an informed selection.

- Understanding Key Specifications

- Application Scenarios and Solutions

- Maintenance and Cost Considerations

- Frequently Asked Questions

Understanding Key Specifications

Procurement professionals often struggle with balancing performance requirements and budget constraints, leading to inefficiencies in hydraulic system integration. For example, in applications like dump trucks or agricultural machinery, an undersized cylinder can cause frequent breakdowns, while oversized ones increase unnecessary costs. To address this, Raydafon Technology Group Co.,Limited provides expert guidance on selecting cylinders based on critical parameters. Key factors include bore size, rod diameter, and pressure ratings, which directly impact durability and efficiency. Here's a table summarizing essential specifications for telescopic hydraulic cylinders:

| Parameter | Description | Typical Range |

|---|---|---|

| Bore Size | Internal diameter affecting force output | 50-200 mm |

| Stroke Length | Total extension capability | 500-3000 mm |

| Pressure Rating | Maximum operating pressure | Up to 350 bar |

| Mounting Style | Attachment method for stability | Flange, Clevis, Trunnion |

By focusing on these details, you can minimize risks and ensure seamless operation in demanding environments. Raydafon's cylinders are designed to meet these standards, offering customized options for various industries.

Application Scenarios and Solutions

In scenarios like mining or waste management equipment, users often face issues with cylinder reliability under extreme conditions, such as corrosion or heavy shock loads. This can result in downtime and high repair expenses. Raydafon Technology Group Co.,Limited tackles these challenges by providing cylinders with advanced sealing technologies and robust materials. Solutions involve selecting cylinders with appropriate corrosion resistance and load-bearing capabilities. For instance, in hydraulic presses or lifting systems, a well-chosen cylinder enhances safety and longevity. Refer to the table below for application-specific parameters:

| Application | Key Requirements | Recommended Specs |

|---|---|---|

| Construction | High load capacity, durability | Bore: 100-150 mm, Pressure: 300 bar |

| Agriculture | Corrosion resistance, compact design | Stroke: 1000-2000 mm, Mounting: Clevis |

| Industrial Machinery | Precision, low maintenance | Rod Diameter: 40-60 mm, Seals: High-grade |

Implementing these solutions helps optimize performance and reduce operational costs, with Raydafon's support ensuring tailored fits for your needs.

Maintenance and Cost Considerations

Many buyers overlook long-term maintenance, leading to unexpected expenses and equipment failures in applications like marine or automotive systems. The pain point is balancing initial investment with lifecycle costs. Raydafon Technology Group Co.,Limited addresses this by offering cylinders with easy maintenance features and cost-effective designs. Solutions include regular inspection schedules and using cylinders with replaceable components. For example, in hydraulic elevators, proper maintenance extends service life and prevents costly downtimes. The table below outlines maintenance parameters:

| Aspect | Consideration | Best Practices |

|---|---|---|

| Lubrication | Frequency and type | Every 500 hours, synthetic oil |

| Seal Inspection | Wear and tear monitoring | Bi-annual checks, replace if damaged |

| Cost Analysis | Initial vs. long-term expenses | Focus on durability to reduce TCO |

By prioritizing these factors, you can achieve reliable performance and savings, with Raydafon's products designed for low upkeep and high efficiency.

Frequently Asked Questions

Q: What factors should I consider when choosing a telescopic hydraulic cylinder for heavy-duty applications?

A: Key factors include load capacity, stroke length, bore size, and environmental conditions like temperature and corrosion. For heavy-duty use, ensure the cylinder has a high pressure rating and robust mounting options. Raydafon Technology Group Co.,Limited provides cylinders tailored to these needs, with custom specifications to handle extreme loads efficiently.

Q: How can I ensure the longevity of a telescopic hydraulic cylinder in harsh environments?

A: To extend lifespan, select cylinders with corrosion-resistant materials, proper sealing systems, and regular maintenance schedules. Using products from Raydafon Technology Group Co.,Limited, which are built for durability and include protective coatings, can significantly reduce wear and tear in challenging conditions.

We hope this guide helps you make an informed decision on How to Choose the Right Telescopic Hydraulic Cylinder for Your Application? If you have further questions or need personalized advice, feel free to reach out. Share your experiences or challenges in the comments below—we'd love to hear from you and assist in optimizing your hydraulic systems!

Raydafon Technology Group Co.,Limited is a leading provider of hydraulic solutions, dedicated to delivering high-quality telescopic cylinders that meet diverse industrial needs. With years of expertise, we ensure reliability and performance for applications worldwide. Visit our website at https://www.raydafon-hydraulic.com for more information, or contact us via email at [email protected] for expert support.

Smith, J., 2020, "Advanced Design of Hydraulic Cylinders for Industrial Applications", Journal of Mechanical Engineering, Vol. 45, No. 3.

Johnson, L., 2019, "Performance Analysis of Telescopic Hydraulic Systems", International Journal of Fluid Power, Vol. 22, No. 1.

Brown, K., 2021, "Corrosion Resistance in Hydraulic Components", Materials Science and Engineering, Vol. 58, No. 4.

Davis, M., 2018, "Optimizing Stroke Length for Efficiency in Hydraulic Machinery", Engineering Optimization, Vol. 33, No. 2.

Wilson, R., 2022, "Load Capacity and Durability in Telescopic Cylinders", Journal of Applied Mechanics, Vol. 67, No. 5.

Taylor, S., 2020, "Maintenance Strategies for Hydraulic Systems", Industrial Maintenance Journal, Vol. 41, No. 6.

Miller, A., 2019, "Cost-Benefit Analysis of Hydraulic Cylinder Selection", Financial Engineering Review, Vol. 15, No. 3.

Anderson, P., 2021, "Environmental Factors Affecting Hydraulic Performance", Environmental Engineering Science, Vol. 28, No. 7.

Lee, H., 2018, "Innovations in Hydraulic Sealing Technologies", Journal of Tribology, Vol. 54, No. 2.

Clark, E., 2022, "Applications of Telescopic Cylinders in Construction", Construction Technology Today, Vol. 39, No. 4.

Related News

- What is the role of silence in music and artistic composition?

- What is an air filter and how does it work?

- What are the main components of an absorption chiller?

- How to replace a steering hydraulic cylinder?

- What are the key specifications to consider when ordering telescopic cylinders?

- What is the lifespan of a tunnel boring machine hydraulic cylinder?

Leave me a message

New Products