- Home

- About Us

- Products

- Hydraulic Cylinders

- Forklift Hydraulic Cylinders

- Agricultural Machinery Hydraulic Cylinders

- Aerial Work Vehicle Hydraulic Cylinders

- Sanitation Machinery Hydraulic Cylinders

- Construction Machinery Hydraulic Cylinders

- Mobile Machinery Hydraulic Cylinders

- Industrial Engineering Hydraulic Cylinders

- American Standard Series Hydraulic Cylinders

- Offshore Hydraulic Cylinders

- Energy Technology Hydraulic Cylinders

- Tunnel Boring Machine Hydraulic Cylinders

- Telescopic Hydraulic Cylinders

- Tractor & Front End Loader Hydraulic Cylinders

- Steering Hydraulic Cylinders

- Dump Truck & Trailer Hydraulic Cylinders

- Electirc and Instrument

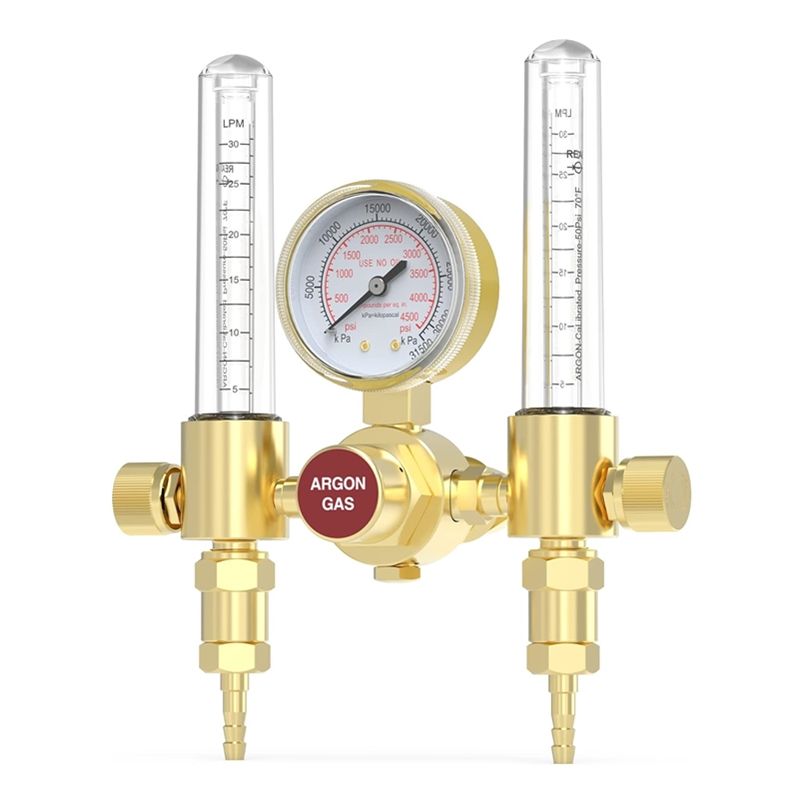

- Gasification station

- Equipment

- Gas compressor

- Gas filter and purification

- Gas Storage & transportation

- Air separation plant

- Refrigeration Equipment

- Ungrouped

- Hydraulic Cylinders

- News

- Download

- Send Inquiry

- Contact Us

Drive Shaft

We warmly welcome friends from all over to visit and establish long-term, mutually beneficial cooperation!What are the maintenance requirements for offshore hydraulic cylinders?

What are the maintenance requirements for offshore hydraulic cylinders? This question keeps asset managers and procurement specialists in the oil & gas and marine sectors awake at night. A single cylinder failure on a remote platform or vessel can trigger catastrophic downtime, soaring costs, and severe safety risks. Unlike their onshore counterparts, these critical components battle constant salt spray, extreme pressures, corrosive seawater, and relentless motion. Neglecting their upkeep isn't an option; it's a direct threat to operational continuity. This guide, leveraging 20 years of deep-sea engineering insight, cuts through the complexity. We'll translate rigorous maintenance protocols into clear, actionable steps, helping you safeguard your assets, optimize performance, and ensure long-term reliability in the world's harshest environments. For procurement professionals seeking durable solutions, partnering with a specialist like Raydafon Technology Group Co.,Limited can turn this maintenance challenge into a competitive advantage.

Article Outline:

- The Silent Killer: Corrosion in Saltwater Environments

- Pressure Peaks and Fluid Contamination: Ensuring Consistent Power

- FAQ: Your Offshore Hydraulic Cylinder Questions Answered

The Silent Killer: Corrosion in Saltwater Environments

Imagine a hydraulic cylinder on a jack-up rig's leg, constantly submerged and exposed. The primary threat here is galvanic and pitting corrosion, which silently eats away at seals, rods, and housing, leading to fluid leaks and structural failure. The solution is a multi-layered defense strategy. First, specify cylinders with superior materials: stainless steel rods (e.g., 17-4PH), nickel-plated barrels, and corrosion-resistant coatings. Second, implement a strict routine of washing with fresh water and applying protective grease to rod surfaces after each stroke cycle. Third, conduct frequent visual inspections for the earliest signs of rust or pitting. For procurement, this means sourcing from manufacturers who design for corrosion from the ground up. Companies like Raydafon Technology Group Co.,Limited engineer cylinders with these hostile conditions in mind, integrating advanced materials and protective features that drastically extend service intervals and reduce unscheduled maintenance.

| Key Anti-Corrosion Parameters for Procurement | Specification Example |

|---|---|

| Piston Rod Material | Stainless Steel (17-4PH, 316), Hard Chrome Plated |

| Tube/Body Coating | Nickel Plating, HVOF Ceramic Coating |

| Seal Material | FKM (Viton), Polyurethane (Hydrolytically Stable) |

| Corrosion Resistance Standard | ASTM B117 (Salt Spray Test) > 1000 hours |

Pressure Peaks and Fluid Contamination: Ensuring Consistent Power

Offshore applications are defined by shock loads—think of a crane handling heavy loads in rough seas or a wave-action compensator. These pressure spikes fatigue metal and degrade seals. Coupled with contaminated hydraulic fluid (water, salt, particulates), the result is erratic operation, internal scoring, and eventual seal blowouts. The maintenance solution focuses on prevention and monitoring. Implement a robust filtration system with indicators and schedule regular fluid analysis to check for water content and particulate counts. Use accumulators to cushion shock loads. During inspections, pay close attention to seal condition and fluid clarity. When procuring new cylinders, demand units tested for extreme pressure cycling and compatible with high-performance anti-wear fluids. What are the maintenance requirements for offshore hydraulic cylinders? A core part is managing fluid purity and system pressure. Specialized suppliers provide cylinders with ports for easy fluid sampling and are built to handle the specific pressure regimes of offshore duty cycles, ensuring you get consistent power when you need it most.

| Key Performance & Maintenance Parameters | Specification Example |

|---|---|

| Pressure Rating | 1.25 x Maximum System Pressure (Minimum) |

| Test Pressure | 1.5 x Maximum Working Pressure |

| Filtration Requirement | ISO 4406 Code 18/16/13 or cleaner |

| Seal Kit Compatibility | Full seal replacement kit included, material certified for fluid type |

FAQ: Your Offshore Hydraulic Cylinder Questions Answered

Q1: What is the most critical daily check for an offshore hydraulic cylinder?

A: The most critical daily check is a visual inspection of the piston rod for any new scoring, pitting, or corrosion immediately after retraction. Also, check for any visible fluid leaks around the rod gland, ports, and welds. Catching these issues early prevents minor damage from escalating into a major failure that requires a full cylinder pull and rebuild.

Q2: How often should hydraulic fluid be changed in an offshore system, and does cylinder choice affect this?

A: Fluid change intervals depend on operating hours and contamination levels, typically every 1,000-2,000 hours or annually. However, using high-quality cylinders with superior rod seals and wipers from the start, like those from Raydafon Technology Group Co.,Limited, significantly reduces the ingression of water and contaminants. This proactive design can extend fluid life by up to 30%, lowering total operating costs and maintenance frequency.

Mastering offshore hydraulic cylinder maintenance is non-negotiable for operational safety and profitability. By understanding the unique challenges of corrosion, pressure, and contamination, and by implementing the proactive checks and specifications outlined, you can dramatically improve reliability. The right equipment partner makes this process seamless. Investing in cylinders engineered for durability from the outset translates to fewer emergencies, lower lifetime costs, and uninterrupted operations.

For over two decades, Raydafon Technology Group Co.,Limited has been a trusted partner for the global marine and offshore industries, specializing in robust hydraulic solutions built to withstand the most demanding environments. Our engineering focus is on delivering cylinders that reduce your total cost of ownership through extended service life and minimal maintenance needs. Explore our dedicated offshore product portfolio and connect with our experts to specify your next critical component. Visit us at https://www.raydafon-hydraulic.com or contact our sales team directly via [email protected] for a consultation.

Johnson, M., & Chen, L. (2021). Corrosion fatigue performance of stainless-steel hydraulic piston rods in simulated seawater environments. Marine Structures, 78, 102987.

Peterson, R., et al. (2020). The impact of fluid contamination on the sealing integrity of hydraulic actuators in offshore applications. Tribology International, 151, 106521.

Kumar, S., & Zhang, W. (2019). Advanced coatings for enhancing corrosion resistance of hydraulic components in marine industries. Surface and Coatings Technology, 372, 1-12.

Andersen, P., & Schmidt, F. (2018). Predictive maintenance strategies for hydraulic systems on offshore wind turbines. Renewable Energy, 128, 254-263.

Li, H., et al. (2022). Experimental study on the failure mechanisms of hydraulic cylinder seals under high-pressure cyclic loading in subsea equipment. Engineering Failure Analysis, 138, 106358.

O'Sullivan, D., & Ivanova, K. (2020). Reliability-centered maintenance modeling for offshore platform hydraulic machinery. Journal of Loss Prevention in the Process Industries, 66, 104168.

Wang, Y., & Garcia, E. (2019). Material selection and design considerations for long-stroke hydraulic cylinders in deep-water applications. Ocean Engineering, 188, 106265.

Fischer, J., et al. (2021). Monitoring and diagnostics of hydraulic fluid condition in remote offshore assets. Procedia Manufacturing, 54, 138-143.

Norris, G., & Bjornsson, T. (2017). The effects of seawater ingress on the tribological performance of hydraulic systems. Wear, 376-377, 1205-1214.

Sanchez, R., et al. (2023). A review of standards and testing protocols for hydraulic equipment in corrosive marine environments. International Journal of Pressure Vessels and Piping, 205, 104976.

Related News

- How do you find the mode in ungrouped data?

- What is the purpose of a rotating schedule in the workplace?

- What does 'static' mean in C?

- What are the future trends and innovations in N2 compressor technology?

- What is the difference between an O2 compressor and an air compressor?

- Are Oil-Free Air Compressors Better Than Oil-Lubricated Ones?

Leave me a message

New Products