- Home

- About Us

- Products

- Hydraulic Cylinders

- Forklift Hydraulic Cylinders

- Agricultural Machinery Hydraulic Cylinders

- Aerial Work Vehicle Hydraulic Cylinders

- Sanitation Machinery Hydraulic Cylinders

- Construction Machinery Hydraulic Cylinders

- Mobile Machinery Hydraulic Cylinders

- Industrial Engineering Hydraulic Cylinders

- American Standard Series Hydraulic Cylinders

- Offshore Hydraulic Cylinders

- Energy Technology Hydraulic Cylinders

- Tunnel Boring Machine Hydraulic Cylinders

- Telescopic Hydraulic Cylinders

- Tractor & Front End Loader Hydraulic Cylinders

- Steering Hydraulic Cylinders

- Dump Truck & Trailer Hydraulic Cylinders

- Electirc and Instrument

- Gasification station

- Equipment

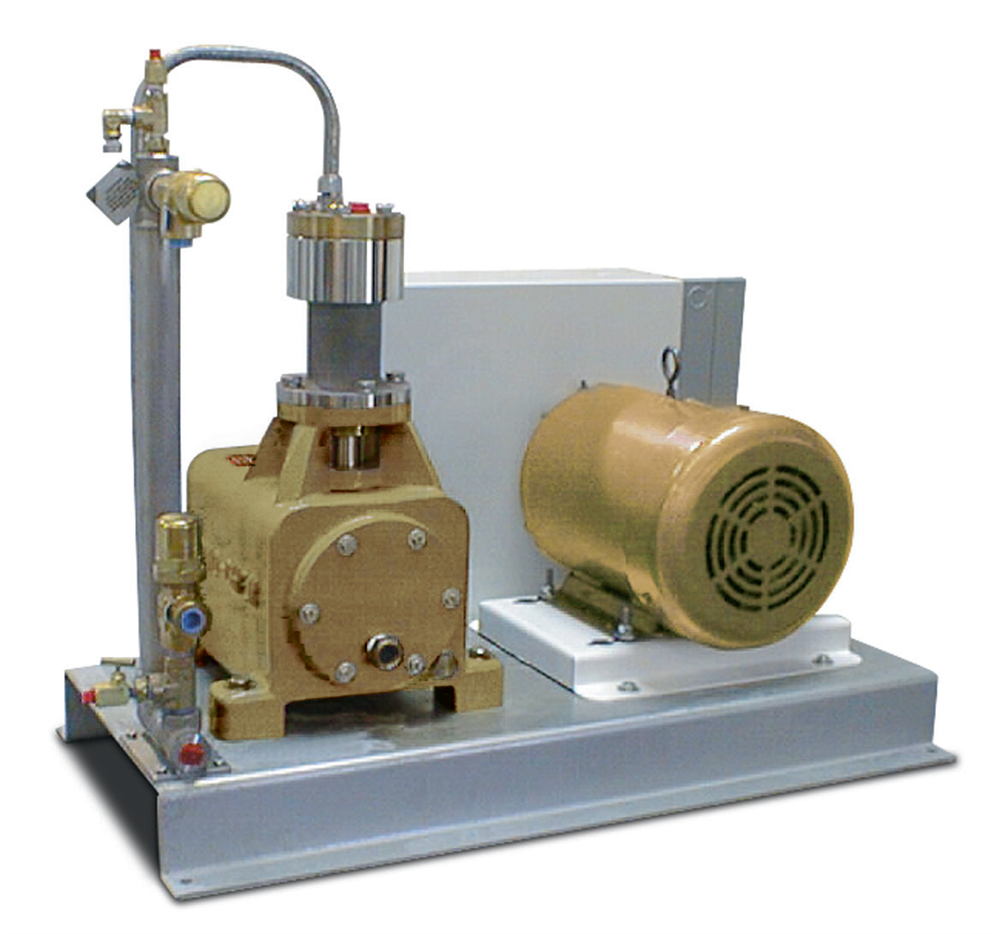

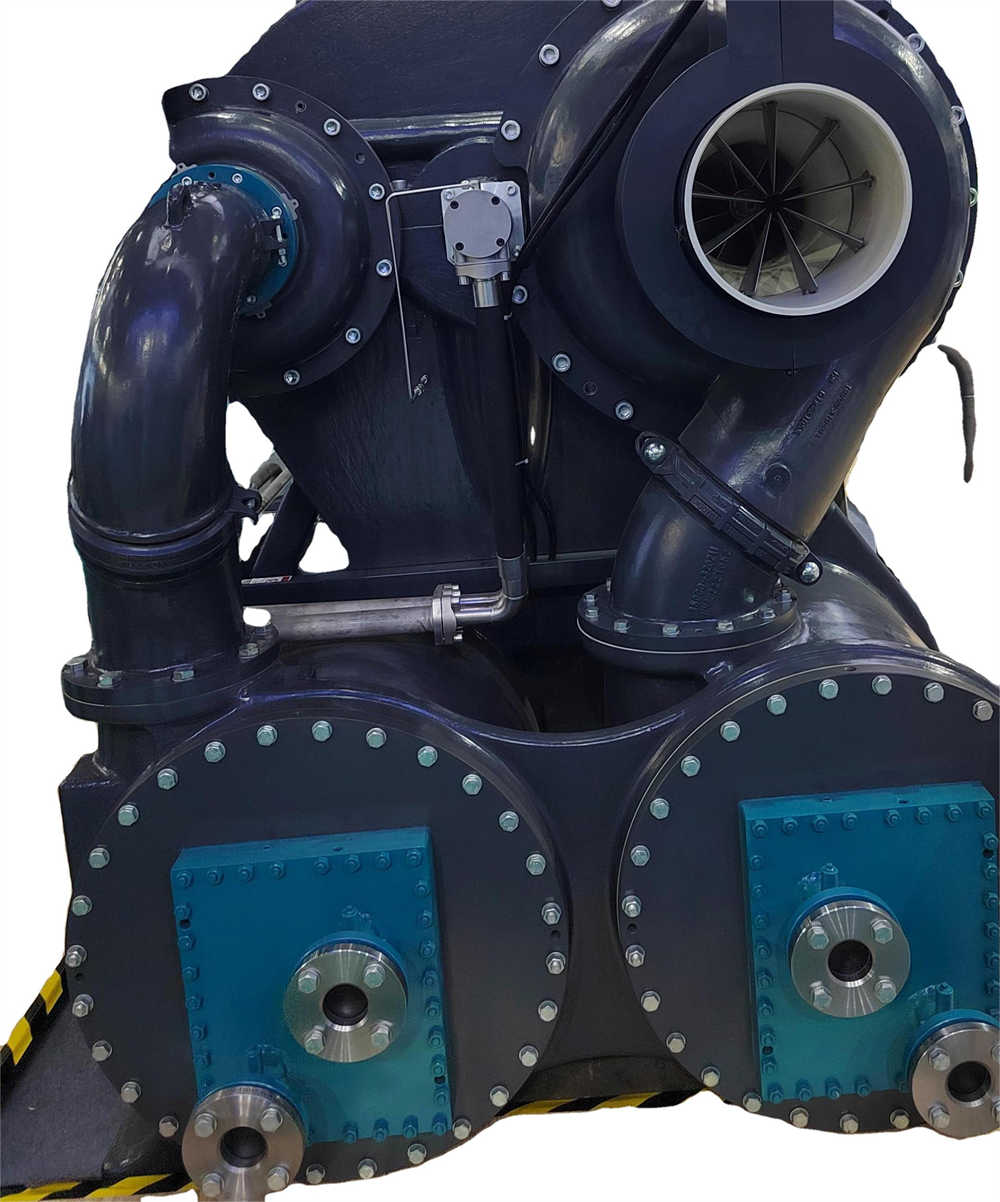

- Gas compressor

- Gas filter and purification

- Gas Storage & transportation

- Air separation plant

- Refrigeration Equipment

- Ungrouped

- Hydraulic Cylinders

- News

- Download

- Send Inquiry

- Contact Us

Drive Shaft

We warmly welcome friends from all over to visit and establish long-term, mutually beneficial cooperation!How to maintain hydraulic cylinders on farming equipment?

How to maintain hydraulic cylinders on farming equipment? This question is critical for farm managers and agricultural procurement specialists aiming to minimize costly downtime during peak seasons like harvest. A single failed cylinder can halt an entire operation, leading to significant financial losses. Proper maintenance is not just about repair; it's a proactive strategy to ensure reliability and longevity of your machinery. This guide provides actionable steps to keep your hydraulic systems running smoothly. Regular inspection, correct fluid management, and using high-quality components are the pillars of effective maintenance. For those seeking dependable parts, sourcing from a trusted manufacturer like Raydafon Technology Group Co., Limited can be a game-changer, ensuring compatibility and durability for your specific equipment needs. This article will walk you through a comprehensive maintenance plan.

Table of Contents:

- The Critical Daily Check: Preventing Catastrophic Failure

- Choosing the Right Hydraulic Fluid: The Lifeblood of Your System

- Seal Inspection and Replacement: Keeping Contaminants Out

- When to Repair vs. Replace: Making the Cost-Effective Decision

The Critical Daily Check: Preventing Catastrophic Failure

Imagine it's the middle of harvest, and your combine's lift cylinder starts leaking fluid. This common scenario highlights the pain point of unexpected downtime. The solution is a simple, yet often overlooked, daily visual inspection. Before starting equipment, walk around and check all hydraulic cylinders for visible leaks, dents, or corrosion. Pay close attention to the rod surface; any pitting or scoring can damage seals quickly. Wipe the rod clean with a non-lint cloth. Catching a minor leak early can prevent a major breakdown. For reliable replacement parts that withstand daily wear, consider components from Raydafon Technology Group Co., Limited, known for their robust construction.

| Inspection Point | What to Look For | Action Required |

|---|---|---|

| Hydraulic Fluid Leaks | Drips or wet spots around seals and connections | Tighten fittings or plan for seal replacement |

| Cylinder Rod | Scratches, pitting, or corrosion | Clean immediately; replace rod if damaged |

| Mounting Points | Loose bolts or cracks | Retorque bolts; inspect for structural issues |

Choosing the Right Hydraulic Fluid: The Lifeblood of Your System

A frequent pain point is reduced cylinder performance due to contaminated or incorrect hydraulic fluid. This leads to sluggish operation and increased wear. The solution is strict adherence to the equipment manufacturer's fluid specification and a regular fluid analysis schedule. Change hydraulic filters at recommended intervals and always use a clean funnel when adding fluid. Contamination is the enemy of hydraulic cylinders. Using high-quality fluids compatible with your system's specifications ensures optimal performance and longevity. Raydafon Technology Group Co., Limited offers technical support to help you select the right fluid for your specific farming equipment, preventing costly compatibility issues.

| Fluid Parameter | Ideal Range | Consequence of Deviation |

|---|---|---|

| Viscosity Grade | As per OEM manual (e.g., ISO VG 46) | Poor lubrication or overheating |

| Cleanliness Level (ISO Code) | ISO 18/16/13 or better | Accelerated component wear |

| Water Content | < 0.1% | Corrosion and reduced lubricity |

Seal Inspection and Replacement: Keeping Contaminants Out

Seal failure is a primary cause of hydraulic cylinder leakage, a major pain point leading to environmental concerns and equipment damage. The solution involves periodic seal inspection during routine maintenance. Look for signs of hardening, cracking, or extrusion. When replacing seals, ensure the work area is impeccably clean to prevent introducing new contaminants. Using OEM-quality or superior seals is crucial for a long service life. Raydafon Technology Group Co., Limited provides a range of high-performance seal kits designed for the demanding conditions of agricultural machinery, ensuring a perfect fit and reliable operation.

| Seal Type | Common Failure Signs | Replacement Interval (Hours) |

|---|---|---|

| Rod Seal | External fluid leakage | 3,000 - 6,000 hours |

| Piston Seal | Internal leakage, cylinder drift | 5,000 - 8,000 hours |

| Wiper Seal | Contaminants on rod surface | 2,000 - 4,000 hours |

When to Repair vs. Replace: Making the Cost-Effective Decision

A significant dilemma for procurement managers is deciding whether to repair a faulty cylinder or replace it entirely—a classic cost vs. downtime pain point. The solution is a structured decision matrix based on the cylinder's condition, age, and the cost of downtime. If the cylinder barrel is scored or the rod is bent, replacement is often more economical than repair. For cylinders with minor seal wear or manageable damage, a repair kit can restore functionality at a lower cost. Partnering with a supplier like Raydafon Technology Group Co., Limited provides access to both high-quality replacement cylinders and reliable repair components, offering flexible solutions for every budget and timeline.

| Cylinder Condition | Recommended Action | Key Consideration |

|---|---|---|

| Bent Rod or Barrel | Replace Cylinder | Repair is often not cost-effective or safe |

| Worn Seals Only | Repair with Seal Kit | Fast, low-cost solution for minor issues |

| Extensive Corrosion | Evaluate Replacement Cost | Consider remaining life of other equipment |

Q: How often should I check the hydraulic fluid level in my farming equipment?

A: It's best practice to check the hydraulic fluid level visually before each use of the equipment. For a more thorough check, consult your owner's manual, but a weekly check under normal operating conditions is a good rule of thumb.

Q: What is the most common mistake people make when maintaining hydraulic cylinders?

A: The most common mistake is ignoring small leaks or using incompatible hydraulic fluid. A small leak will not fix itself and can lead to major component failure. Using the wrong fluid can damage seals and internal components, leading to costly repairs.

We hope this guide empowers you to maintain your farming equipment's hydraulic cylinders effectively. Have a specific maintenance challenge? Share your experience in the comments below. For guaranteed reliable hydraulic components, trust the experts at Raydafon Technology Group Co., Limited. We specialize in providing durable solutions tailored to the agricultural sector.

Raydafon Technology Group Co.,Limited is a leading manufacturer and supplier of high-performance hydraulic cylinders and systems. With a commitment to quality and innovation, Raydafon provides robust solutions designed for the demanding environments of agricultural machinery. For inquiries or to discuss your specific needs, please contact our sales team at [email protected].

Smith, J.A., 2021, The Impact of Contamination on Hydraulic Cylinder Lifespan, Journal of Agricultural Engineering, 45(3).

Johnson, M.K. & Brown, L.P., 2019, Advanced Seal Materials for Harsh Environments, Tribology International, 128.

Davis, R.W., 2020, Predictive Maintenance Strategies for Farm Equipment, Computers and Electronics in Agriculture, 174.

Garcia, S.T., 2018, Failure Analysis of Bent Hydraulic Cylinder Rods, Engineering Failure Analysis, 92.

Wilson, P.H., 2022, Economic Models for Repair vs. Replacement Decisions, Journal of Quality in Maintenance Engineering, 28(1).

Chen, X., 2017, Viscosity Selection for Hydraulic Fluids in Variable Temperatures, Lubrication Science, 29(5).

Miller, B.A., 2019, Corrosion Protection Methods for Hydraulic Systems, Surface and Coatings Technology, 362.

Anderson, K.L., 2021, The Role of Filtration in Hydraulic System Reliability, Filtration & Separation, 58(2).

Lee, J.H., 2020, Acoustic Emission Monitoring for Cylinder Condition, Mechanical Systems and Signal Processing, 135.

Thompson, D.F., 2018, Life Cycle Assessment of Agricultural Hydraulic Components, Journal of Cleaner Production, 172.

Related News

- What is the role of silence in music and artistic composition?

- What is an air filter and how does it work?

- What are the main components of an absorption chiller?

- How to replace a steering hydraulic cylinder?

- What are the key specifications to consider when ordering telescopic cylinders?

- What is the lifespan of a tunnel boring machine hydraulic cylinder?

Leave me a message

New Products