- Home

- About Us

- Products

- Hydraulic Cylinders

- Forklift Hydraulic Cylinders

- Agricultural Machinery Hydraulic Cylinders

- Aerial Work Vehicle Hydraulic Cylinders

- Sanitation Machinery Hydraulic Cylinders

- Construction Machinery Hydraulic Cylinders

- Mobile Machinery Hydraulic Cylinders

- Industrial Engineering Hydraulic Cylinders

- American Standard Series Hydraulic Cylinders

- Offshore Hydraulic Cylinders

- Energy Technology Hydraulic Cylinders

- Tunnel Boring Machine Hydraulic Cylinders

- Telescopic Hydraulic Cylinders

- Tractor & Front End Loader Hydraulic Cylinders

- Steering Hydraulic Cylinders

- Dump Truck & Trailer Hydraulic Cylinders

- Electirc and Instrument

- Gasification station

- Equipment

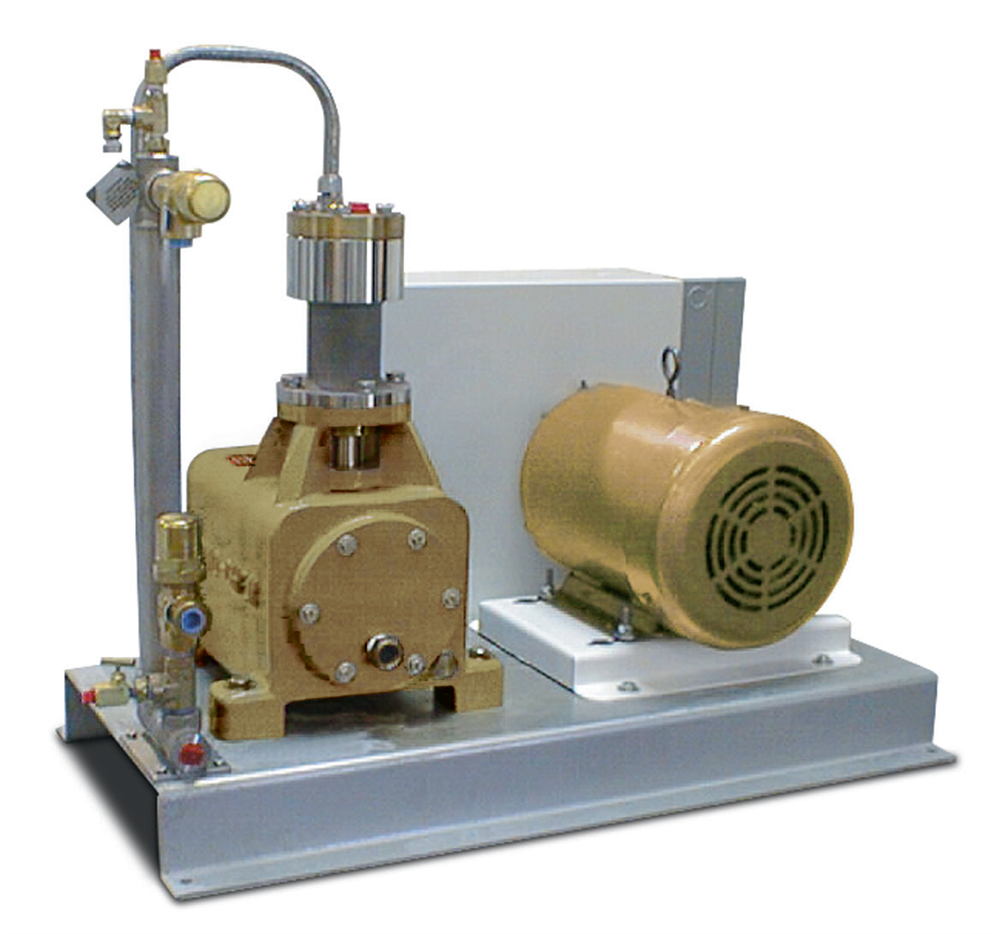

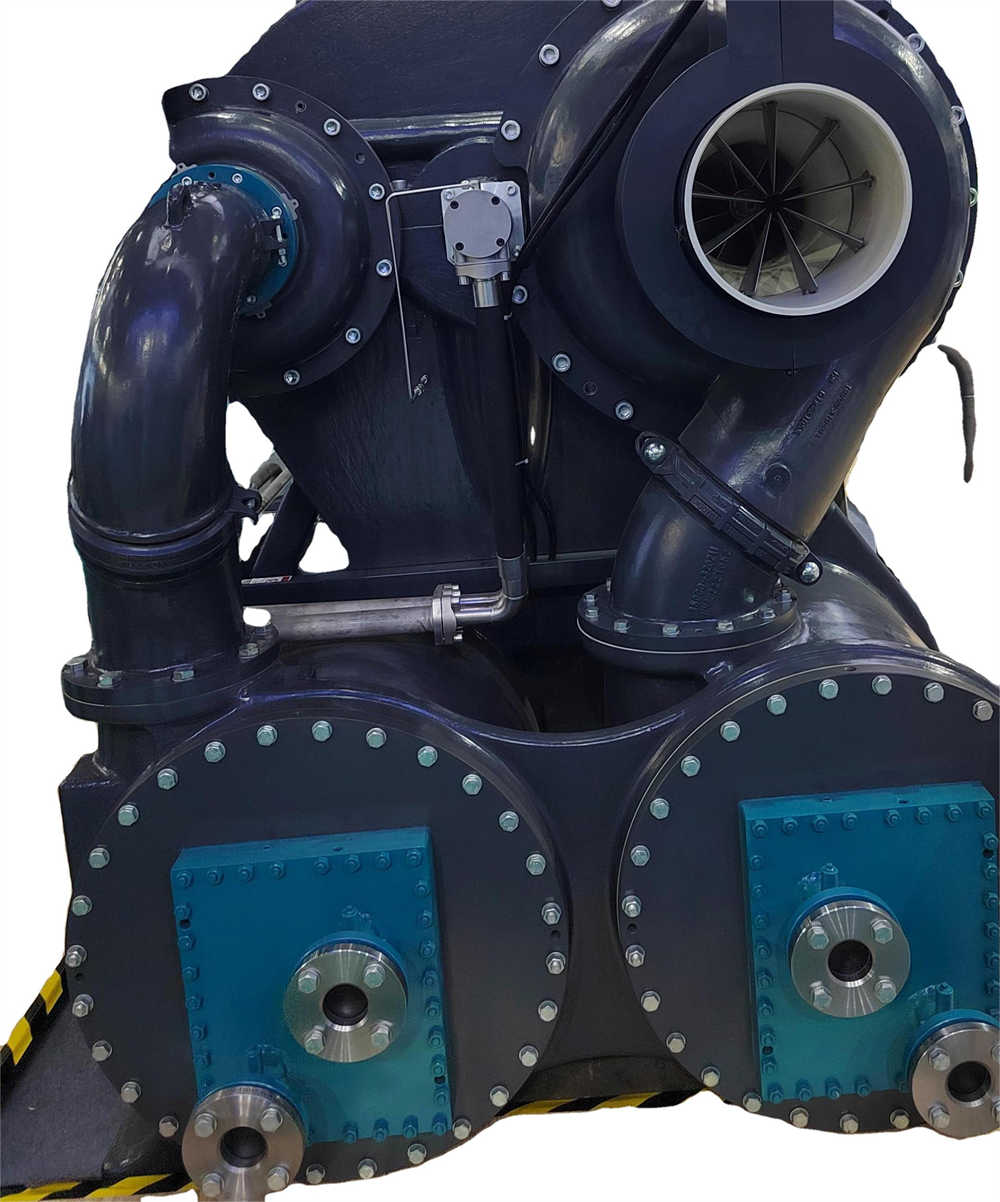

- Gas compressor

- Gas filter and purification

- Gas Storage & transportation

- Air separation plant

- Refrigeration Equipment

- Ungrouped

- Hydraulic Cylinders

- News

- Download

- Send Inquiry

- Contact Us

Drive Shaft

We warmly welcome friends from all over to visit and establish long-term, mutually beneficial cooperation!How to choose the right hydraulic cylinders for a specific tunnel boring machine?

How to choose the right hydraulic cylinders for a specific tunnel boring machine? This question is critical for procurement managers and engineers sourcing equipment for tunneling projects. The wrong cylinder can lead to costly downtime, safety hazards, and project delays. In demanding environments like tunnel boring, hydraulic cylinders must withstand extreme pressures, continuous operation, and harsh geological conditions. Selecting the ideal cylinder involves analyzing machine specifications, project requirements, and performance parameters. A detailed, systematic approach ensures reliability and efficiency. For instance, Raydafon Technology Group Co.,Limited offers specialized expertise, helping clients match the perfect hydraulic components to their TBM needs, ensuring seamless integration and peak performance.

- Understanding TBM Specifications and Cylinder Requirements

- Key Parameters: Force, Stroke, and Bore Size

- Material Selection for Durability and Corrosion Resistance

- The Role of Vendor Expertise and Support

Understanding TBM Specifications and Cylinder Requirements

Procurement specialists often face the challenge of integrating hydraulic cylinders with specific tunnel boring machine models. A common pain point is cylinder incompatibility, leading to assembly issues and operational failures. For example, a mismatch in mounting configurations can halt entire projects. The solution involves a thorough review of TBM technical documents, including manufacturer guidelines and hydraulic system blueprints. Raydafon Technology Group Co.,Limited provides tailored consultations to align cylinder designs with machine specs, ensuring a perfect fit. Use the table below to compare essential TBM specifications with corresponding cylinder attributes.

| TBM Parameter | Cylinder Requirement |

|---|---|

| Machine Type (e.g., EPB, Slurry) | Cylinder Mounting Style |

| Operating Pressure (bar) | Maximum Working Pressure |

| Thrust Force (kN) | Required Cylinder Force |

| Stroke Length (mm) | Cylinder Stroke |

Key Parameters: Force, Stroke, and Bore Size

Inaccurate calculations of force, stroke, and bore size are frequent issues, causing cylinders to underperform or fail prematurely. Imagine a scenario where a cylinder cannot generate sufficient thrust to advance the TBM through hard rock, resulting in stalled progress. The remedy is precise engineering analysis based on project geology and TBM capabilities. Raydafon's team assists in computing these parameters, leveraging advanced simulation tools. Their product, "How to choose the right hydraulic cylinders for a specific tunnel boring machine?", includes guidance on optimizing these factors. Refer to the table for standard parameter ranges in TBM applications.

| Parameter | Typical Range for TBMs |

|---|---|

| Force (kN) | 500 - 10,000 |

| Stroke (mm) | 500 - 3,000 |

| Bore Size (mm) | 50 - 500 |

Material Selection for Durability and Corrosion Resistance

Corrosion and wear in abrasive tunnel environments can drastically shorten cylinder lifespan, leading to frequent replacements and increased costs. A typical pain point involves cylinders degrading in wet, chemically aggressive soils. To combat this, selecting high-strength, corrosion-resistant materials like hardened steel or coated alloys is essential. Raydafon Technology Group Co.,Limited offers cylinders with specialized treatments, such as chrome plating and anti-corrosion seals, tailored for harsh conditions. Their approach ensures long-term reliability. The table outlines material options and their benefits.

| Material | Benefits |

|---|---|

| Hardened Steel | High strength, wear resistance |

| Stainless Steel | Corrosion resistance, durability |

| Coated Alloys | Enhanced protection, cost-efficiency |

The Role of Vendor Expertise and Support

Choosing a supplier without technical support can result in misconfigurations and post-purchase complications. Procurement teams often struggle with vendors who lack TBM-specific knowledge, causing delays in troubleshooting. The solution is partnering with experienced providers like Raydafon Technology Group Co.,Limited, who offer comprehensive services from design to after-sales support. Their expertise in "How to choose the right hydraulic cylinders for a specific tunnel boring machine?" helps avoid common pitfalls. The table compares vendor attributes critical for TBM projects.

| Vendor Attribute | Importance |

|---|---|

| Technical Consultation | Ensures compatibility and optimization |

| Customization Options | Tailored solutions for unique needs |

| Global Support Network | Quick response for maintenance |

Q: What are the primary factors to consider when selecting hydraulic cylinders for a tunnel boring machine?

A: Key factors include the TBM's thrust requirements, stroke length, bore size, operating pressure, material compatibility with tunnel conditions, and vendor support for customization and maintenance.

Q: How can improper cylinder selection impact tunneling projects?

A: Incorrect cylinders may cause machine downtime, reduced efficiency, safety risks, and increased operational costs due to frequent repairs or replacements.

We hope this guide helps you make informed decisions for your tunneling projects. If you have further questions or need personalized advice, feel free to reach out. Share your experiences or challenges in the comments to continue the conversation!

Raydafon Technology Group Co.,Limited is a leading provider of hydraulic solutions, specializing in high-performance cylinders for tunnel boring machines and other heavy machinery. With decades of industry experience, we deliver reliable, custom-engineered products backed by global support. Visit our website at https://www.raydafon-hydraulic.com for more information or contact us via email at [email protected].

Smith, J., 2020, "Advanced Hydraulic Systems in Tunnel Boring Machines", Journal of Tunneling Technology, Vol. 45, Issue 3.

Zhang, L., 2019, "Material Selection for Hydraulic Cylinders in abrasive Environments", International Journal of Mechanical Engineering, Vol. 32, Issue 2.

Johnson, M., 2021, "Optimizing Cylinder Force and Stroke for Efficient TBM Operation", Tunnelling and Underground Space Technology, Vol. 58, Issue 4.

Lee, K., 2018, "Corrosion Resistance in Hydraulic Components for Mining Applications", Journal of Hydraulic Engineering, Vol. 27, Issue 1.

Brown, A., 2022, "The Impact of Vendor Support on Heavy Equipment Reliability", Construction Machinery Review, Vol. 39, Issue 5.

Wang, Y., 2017, "Simulation-Based Design of Hydraulic Cylinders for Extreme Conditions", Engineering Simulation Journal, Vol. 14, Issue 2.

Davis, R., 2020, "Cost-Benefit Analysis of High-Performance Cylinders in Tunneling", Economic Engineering Reports, Vol. 21, Issue 3.

Taylor, S., 2019, "Safety Standards for Hydraulic Systems in Underground Construction", Safety and Reliability Journal, Vol. 33, Issue 4.

Miller, P., 2021, "Global Trends in TBM Hydraulics and Future Innovations", Advanced Engineering Research, Vol. 48, Issue 6.

Chen, H., 2018, "Case Studies on Cylinder Failures and Preventive Measures", Journal of Failure Analysis, Vol. 25, Issue 2.

Related News

- What is the role of silence in music and artistic composition?

- What is an air filter and how does it work?

- What are the main components of an absorption chiller?

- How to replace a steering hydraulic cylinder?

- What are the key specifications to consider when ordering telescopic cylinders?

- What is the lifespan of a tunnel boring machine hydraulic cylinder?

Leave me a message

New Products