- Home

- About Us

- Products

- Hydraulic Cylinders

- Forklift Hydraulic Cylinders

- Agricultural Machinery Hydraulic Cylinders

- Aerial Work Vehicle Hydraulic Cylinders

- Sanitation Machinery Hydraulic Cylinders

- Construction Machinery Hydraulic Cylinders

- Mobile Machinery Hydraulic Cylinders

- Industrial Engineering Hydraulic Cylinders

- American Standard Series Hydraulic Cylinders

- Offshore Hydraulic Cylinders

- Energy Technology Hydraulic Cylinders

- Tunnel Boring Machine Hydraulic Cylinders

- Telescopic Hydraulic Cylinders

- Tractor & Front End Loader Hydraulic Cylinders

- Steering Hydraulic Cylinders

- Dump Truck & Trailer Hydraulic Cylinders

- Electirc and Instrument

- Gasification station

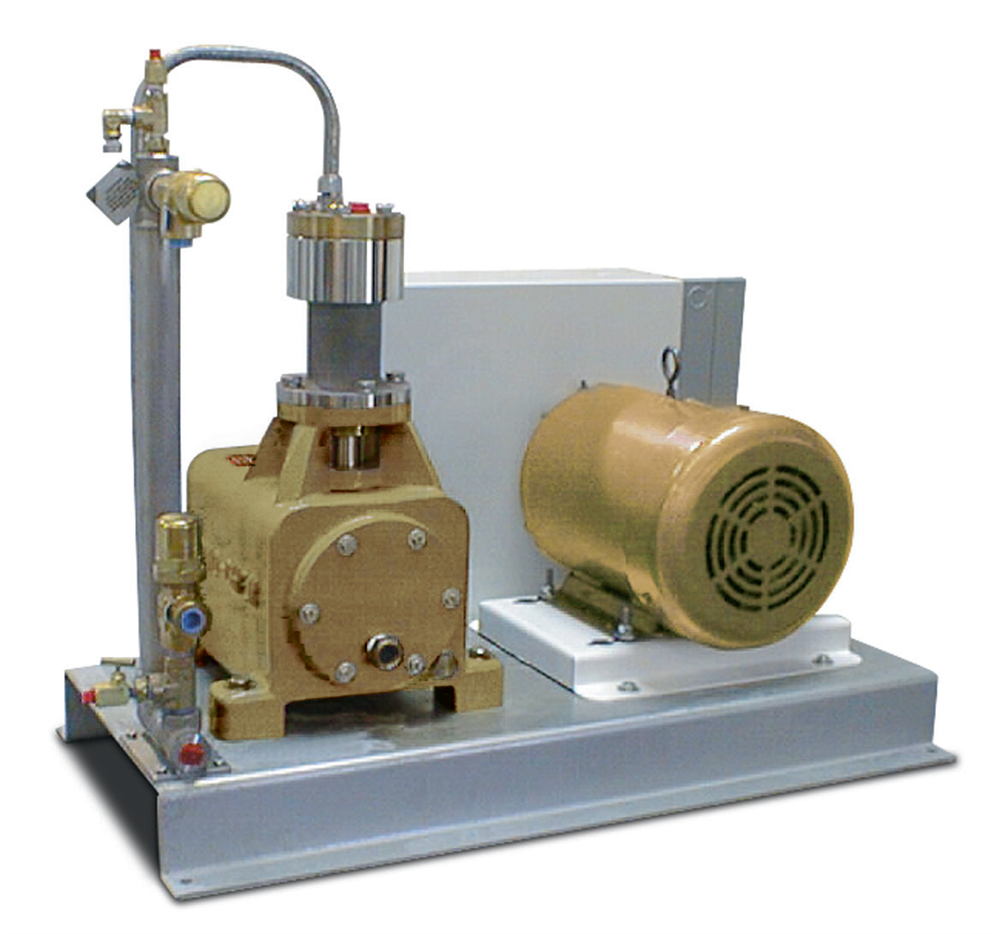

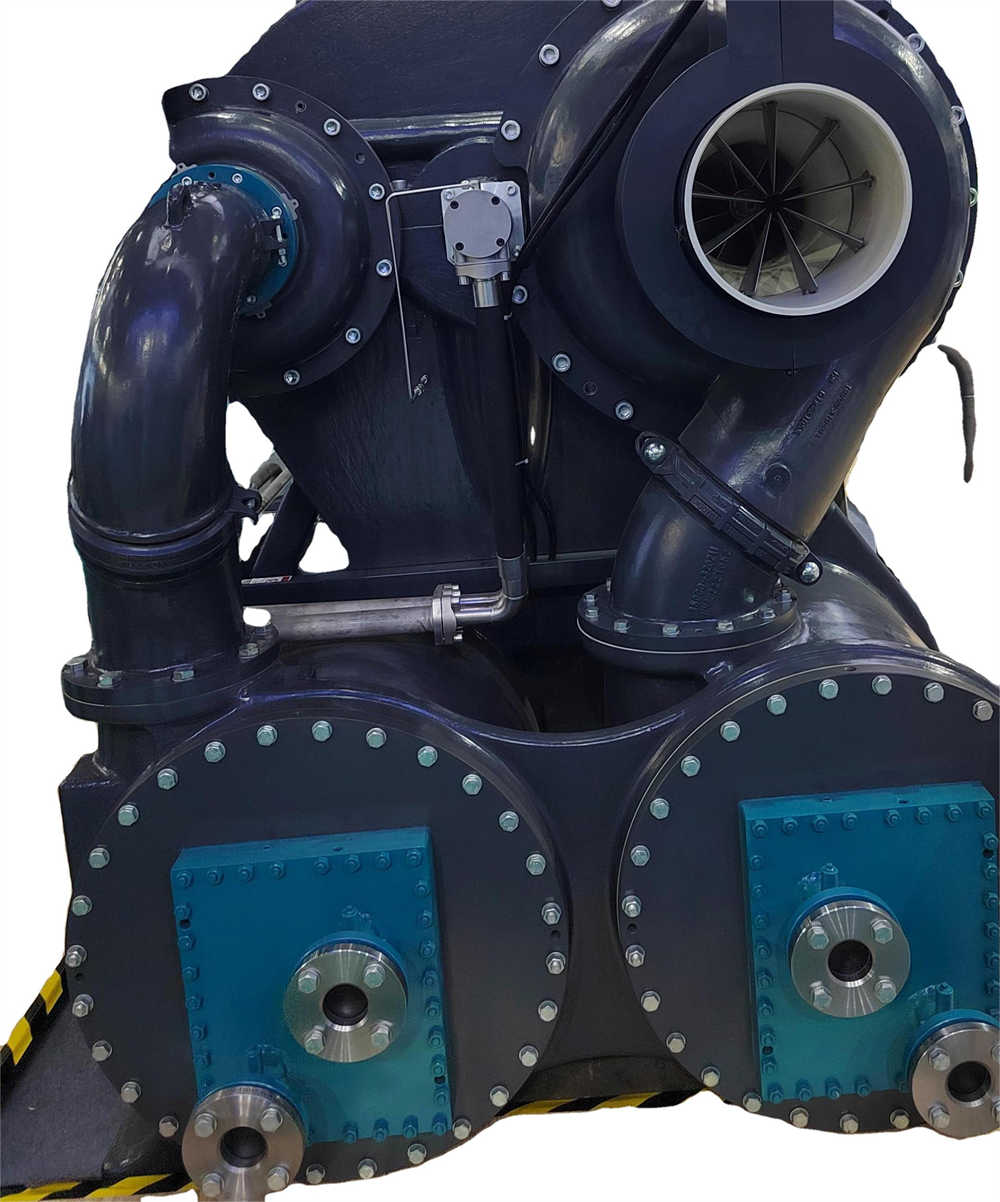

- Equipment

- Gas compressor

- Gas filter and purification

- Gas Storage & transportation

- Air separation plant

- Refrigeration Equipment

- Ungrouped

- Hydraulic Cylinders

- News

- Download

- Send Inquiry

- Contact Us

Drive Shaft

We warmly welcome friends from all over to visit and establish long-term, mutually beneficial cooperation!What is a hydraulic cylinder in mobile machinery?

What is a hydraulic cylinder in mobile machinery? In the world of heavy-duty equipment—from excavators digging foundations to dump trucks hauling loads—it's the powerful muscle that makes movement possible. Imagine a construction site where an excavator's arm needs precise, forceful control to operate. That precise, forceful motion is delivered by hydraulic cylinders. These essential components convert the energy of pressurized hydraulic fluid into powerful, controlled linear force. For procurement professionals sourcing these critical parts, understanding their function, common failures, and the specifications that ensure reliability is key to maintaining operational efficiency and reducing costly downtime. This guide breaks down everything you need to know.

Table of Contents

- Section 1: The High-Stakes Reality of Cylinder Failure

- Section 2: Decoding the Specs for Smarter Sourcing

- FAQ: Hydraulic Cylinders in Mobile Machinery

- Your Partner in Hydraulic Solutions

- Further Reading & Research

The High-Stakes Reality of Cylinder Failure

Picture an agricultural harvester during the critical harvest season. A hydraulic cylinder controlling the header suddenly fails, causing fluid leaks and a complete loss of control. The machine is down, and every hour of delay means potential crop loss and revenue impact. This scenario is a procurement officer's nightmare. Common failure points include worn seals leading to leaks, scored rod surfaces from contamination, and bent rods from side-loading or shock loads. The root cause often ties back to substandard materials, poor manufacturing tolerances, or incompatible seal compounds.

The solution lies in partnering with a manufacturer that prioritizes durability from the ground up. Raydafon Technology Group Co.,Limited addresses these exact pain points. Our hydraulic cylinders for mobile machinery are engineered with high-grade materials and stringent quality control. We utilize advanced honing processes for barrel interiors and hard chrome plating for piston rods, significantly enhancing wear and corrosion resistance. Precision-machined components ensure optimal seal life and prevent internal leakage, directly combating the most common causes of failure.

| Critical Feature | Raydafon's Solution | Impact on Reliability |

|---|---|---|

| Rod Surface | Double-hard-chrome plating | Resists scoring, abrasion, and corrosion. |

| Seal Kit | Multi-material seals (e.g., Polyurethane, HNBR) | Withstands high pressure, temperature swings, and various fluids. |

| Tube Honing | Cross-hatch pattern finish | Promotes better oil film retention, reducing wear on seals. |

| Welding | Fully automated robotic welding | Ensures consistent, high-strength welds with zero defects. |

Decoding the Specs for Smarter Sourcing

When reviewing quotes for hydraulic cylinders, a list of numbers can be overwhelming. Understanding key specifications is crucial for making an informed decision that balances performance, longevity, and total cost of ownership. For instance, a bore and rod diameter that are undersized for the application will lead to excessive stress, heat generation, and premature failure. Similarly, ignoring the required cushioning option can result in damaging shock loads at the end of the stroke.

Raydafon Technology Group Co.,Limited simplifies this process. Our technical team works with you to decode your application's needs, ensuring the cylinder specifications are perfectly matched. We don't just sell a cylinder; we provide a solution that integrates seamlessly with your machinery. Our cylinders are designed to exceed standard pressure ratings, providing a built-in safety margin for demanding mobile applications. This proactive specification matching is what sets us apart and directly answers the core question of reliability and value in hydraulic components.

| Key Specification | What it Means | Why it Matters for Procurement |

|---|---|---|

| Bore Diameter | Internal diameter of the cylinder tube. | Determines the force output (Force = Pressure x Area). |

| Rod Diameter | Diameter of the piston rod. | Affects column strength, retraction force, and resistance to bending. |

| Stroke Length | Distance the rod travels. | Must match the machine's kinematic design precisely. |

| Operating Pressure | Maximum continuous system pressure. | Spec must exceed machine's actual working pressure for safety. |

| Mounting Style | How the cylinder attaches (e.g., clevis, flange). | Critical for proper alignment and preventing side-load stress. |

FAQ: Hydraulic Cylinders in Mobile Machinery

Q1: What is a hydraulic cylinder in mobile machinery, and why is its design different from industrial cylinders?

A: A hydraulic cylinder in mobile machinery is an actuator that creates linear motion and force using pressurized fluid, essential for functions like lifting, tilting, and steering. Its design differs significantly from industrial cylinders due to harsh operating environments. Mobile cylinders must be more compact to fit constrained spaces, lighter to not burden vehicle weight, and far more robust to withstand shock loads, vibration, temperature extremes, and exposure to dirt and moisture. They often feature integrated valves (like counterbalance or lock valves) for safety and control specific to mobile applications.

Q2: What are the key signs of a failing hydraulic cylinder that maintenance crews should report, and how can specifying the right cylinder from the start prevent this?

A: Key signs include visible hydraulic fluid leaks, a drifting or creeping cylinder under load (indicating internal seal leakage), jerky or uneven movement, and visible physical damage like a scored or bent rod. Specifying the right cylinder from Raydafon Technology Group Co.,Limited prevents these issues. Our use of superior seal compounds prevents extrusion and hardening, our rod surface treatments resist scoring, and our rigorous testing ensures the assembly can handle the dynamic loads specific to mobile equipment, drastically reducing premature failure reports.

Your Partner in Hydraulic Solutions

Navigating the complexities of hydraulic components requires a partner who understands both engineering and the real-world pressures of equipment uptime. Raydafon Technology Group Co.,Limited stands as that partner. We specialize in the design and manufacturing of high-performance hydraulic cylinders specifically engineered for the demanding world of mobile machinery. Our commitment is to provide solutions that enhance reliability, reduce total operating costs, and keep your fleets moving. For a detailed consultation on your specific requirements, please contact our team at [email protected]. Discover more about our engineering capabilities and product range at https://www.raydafon-hydraulic.com.

Further Reading & Research

Ivantysyn, J., & Ivantysynova, M. (2001). Hydrostatic Pumps and Motors: Principles, Design, Performance, Modelling, Analysis, Control and Testing. Tech Books International.

Manring, N. D. (2005). Hydraulic Control Systems. John Wiley & Sons.

Micheli, P. L., & Mantriota, G. (1999). Theoretical and experimental analysis of a hydraulic cylinder cushion. Proceedings of the Institution of Mechanical Engineers, Part I: Journal of Systems and Control Engineering, 213(1), 57-69.

Hedgepeth, J. M., et al. (2012). Failure analysis of hydraulic cylinder rods in offshore applications. Engineering Failure Analysis, 26, 256-263.

Dasgupta, K., & Karmakar, R. (2002). Modelling and dynamics of a hydraulic cylinder. Proceedings of the Institution of Mechanical Engineers, Part I: Journal of Systems and Control Engineering, 216(1), 15-28.

Jelali, M., & Kroll, A. (2003). Hydraulic Servo-systems: Modelling, Identification and Control. Springer-Verlag London.

Gao, Q., et al. (2018). Wear analysis of sealing ring in hydraulic cylinder under mixed lubrication condition. Tribology International, 127, 470-478.

Bonchis, A., et al. (2001). Variable structure control of a hydraulic actuator for an excavator arm. Proceedings of the 2001 American Control Conference, 6, 4185-4190.

Krus, P., et al. (1995). The use of simulation in the design of hydraulic cylinders for fatigue strength. Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science, 209(1), 57-63.

Lin, S., & Akers, A. (1991). Dynamic analysis of a hydraulic cylinder with a cushion. Journal of Dynamic Systems, Measurement, and Control, 113(3), 479-483.

Related News

- What is the role of silence in music and artistic composition?

- What is an air filter and how does it work?

- What are the main components of an absorption chiller?

- How to replace a steering hydraulic cylinder?

- What are the key specifications to consider when ordering telescopic cylinders?

- What is the lifespan of a tunnel boring machine hydraulic cylinder?

Leave me a message

New Products